- Hydraulic Tank Jack

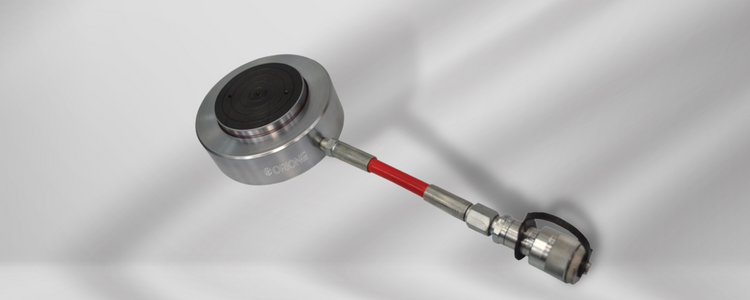

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

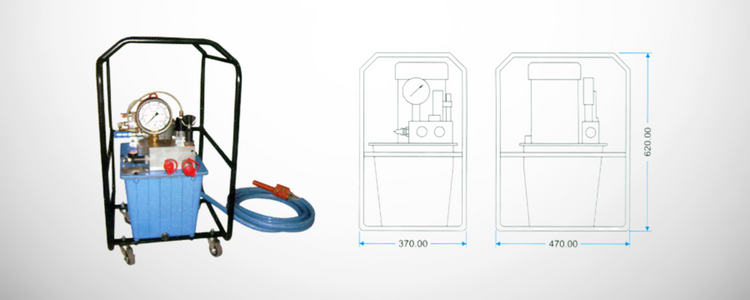

- Hydraulic Hand Pumps Aluminium

Hydraulic Pullers Suppliers

Do you want high-quality Hydraulic Pullers at an affordable price? You arrive at the right place. We are the best manufacturers and suppliers of Hydraulic Pullers in India.

This information will explain more about Our Hydraulic Pullers.

Continue reading further below.

Introduction

If you need the correct Puller, removing parts attached to a shaft can be challenging and take a long time. Interference fits, dirt, and rust can make it hard to take something apart.

There are obvious safety risks if you cut, torch, or hammer instead of using a puller. Also, there is a chance that you will damage the parts of the machine you are trying to fix!

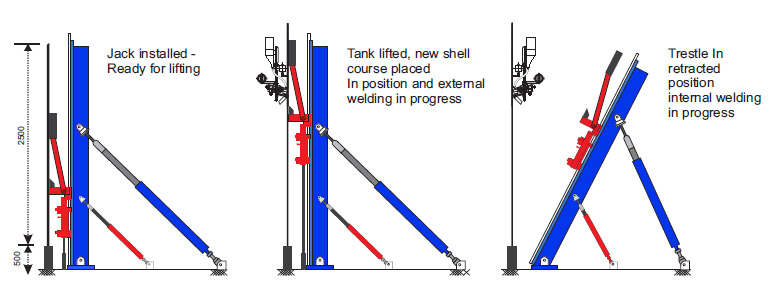

Mechanical and hydraulic pullers are excellent tools for removing parts in various industries. Technicians often use more minor pullers in places like small auto repair shops. Heavy industries use models like the ones in the diagram below, which are bigger and can carry more weight.

When a puller is needed for a project, it's usually to fix something that spins. Bearings, gears, wheels, pins, bushings, sleeves, couplers, sprockets, and pulleys are all standard parts to take off.

What is Hydraulic Puller?

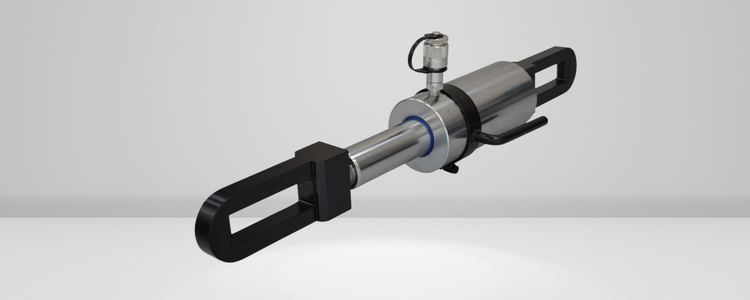

A hydraulic puller removes shaft components such as bearings, pulleys, and gears. Hydraulic pullers usually have two or three legs that go around the part that needs to be removed and a forcing screw that centers up against the end of a shaft. These pullers work well because they use controlled hydraulic forces to separate parts quickly, especially compared to manual methods. When appropriately used, hydraulic pullers don't damage any parts for maintenance, which can be important when time is of the essence.

Features of Hydraulic Pullers

Two or Three Jaws?

As was said above, a 3 jaw puller is best to use when there's sufficient space. They are easier to use and safer.

Hydraulic vs Mechanical

Hydraulic pullers are easier to use than mechanical ones, but you'll need a pump, hose, and gauge to use one. Depending on the size of the Puller, you can use your hands, air, or electricity to power the pump.

Reach

The reach is the distance between the jaw's pulling surface and the Puller's jaw head. This distance changes as the jaws move apart. The reach-to-diameter ratio of Enerpac lock grip pullers is excellent. This is because their cage system is different from what other people use. Also, the inside shape of the jaws makes it possible to pull deeper parts.

Synchronous and Self-Centering Jaws

Enerpac lock grip pullers have a synchronous feature that allows all jaws to move simultaneously. Because of this feature, the spindle stays in the middle of the shaft. This prevents misalignment and makes setup more accessible and faster.

Locking Mechanism

The locking mechanism keeps the jaws from coming off the application during the pulling process. When the handle is turned, the jaws are locked onto the application. This lets the shaft-mounted part be pulled free when the spindle is rotated.

Spread

The spread is just the jaws' diameter when they are open. Most often, up to 25 inches

Tonnage

There are many different sizes and strengths of pullers. Most models you can choose from weigh between 2 and 64 imperial tons. On the other hand, Enerpac has 100-ton puller units with two or three jaws made for specific jobs. These oversized, heavy items are put on a cart with a lift and hydraulic pump.

Note: We are the best Hydraulic Pullers Manufacturers and Suppliers in Navi Mumbai, India. We offer Hydraulic Pullers at lowest price.

Advantages of Hydraulic Pullers

A hydraulic puller is a great new tool instead of a regular puller. The hydraulic Puller is small, light, easy to carry, flexible, saves time and effort, and doesn't slip. And it is not limited by place, direction (0-360°), or position (2 claws, 3 claws). It is often used to remove discs, flanges, gears, bearings, pulleys, etc.

Applications of Hydraulic Pullers

Hydraulic pullers are used to take off parts that are attached to a shaft (bearings or couplings). Pullers use controlled hydraulic force to get the job done and can separate the parts quickly (especially when doing it by hand). Hydraulic pullers also don't hurt the details, which is essential when doing maintenance work.

Orione Hydro Power sells different hydraulic puller sets. The puller sets come in different sizes and can come with more than one hydraulic cylinder. We can even deliver cylinders manufactured following your specifications for your application. The puller sets come with the pump and other system parts, but sometimes not the cylinder. Since there are so many different kinds of hydraulic cylinders, these should be made to fit the pullers.

Types of Hydraulic Pullers

There are different types of pullers to choose from. If you choose the one that works best for your job, you'll get the job done quickly, safely, and without doing any damage.

Two Jaw and Three Jaw Pullers

Most pullers have either 3 jaws or 2 jaws. Most people use 3 jaw pullers because the additional jaw helps spread the force more evenly. But a two-jaw puller may be utilized when access is limited, as long that it's used carefully.

Mechanical and Hydraulic Pullers

Mechanical pullers move the center bolt or force screw toward the shaft by turning a crossbar.

Hydraulic pullers have a hydraulic cylinder that is built in. It is driven by a pump to apply the force that is needed. The thrust is then applied directly, without twisting, by the plunger. It is more effective and safer.

Several tools are made to take out bearings if that's what you want. For example, Enerpac sells pullers, separators, and cup pullers for bearings.

Internal Pullers

These take off parts on shafts when there is no spindle support. With a slide hammer attached to an internal puller, it is possible to use a high-impact force.

Working of Hydraulic Pullers

The hydraulic Puller moves with the hydraulic starting rod, preventing the push rod from rotating. The thread makes it easy to move the hook seat forward or backward. During use, as long as the handle is moved back and forth just a little bit, the hydraulic starter rod moves forward, and the hook moves back to pull out the object being pulled.

How to Use Hydraulic Pullers

1. When using the integrated hydraulic Puller, insert the slotted end of the handle into the oil return valve stem and tighten the oil return valve stem clockwise.

2. Set the claw seat on the hydraulic puller hook so that the claw hook grabs the thing being pulled.

3. Place the handle in the lifter hole. Tilt the piston starter rod back and forth to move smoothly forward, and the claw hook will move around to pull the object out.

4. The effective distance of the hydraulic Puller's piston-starting rod is only 50mm, so the extension distance shouldn't exceed 50mm when used. Stop when it is not pulled out, loosen the oil return valve, let the piston start rod go back in, and do steps 1, 2, and 3 again after adjusting until it is pulled out.

5. To pull back the piston start rod, use the slotted end of the handle to slightly loosen the oil return valve rod by turning it counterclockwise. The spring will then pull the piston start rod back slowly.

How To Select Proper Hydraulic Puller?

A few things could affect which hydraulic Puller you choose for your job. Size is one thing that needs to be taken into account. Another thing to consider is the required force, which can be affected by things like the bearing age or gear taken off and how the system works (heavy-duty farming vs. a relatively clean factory indoors). Each set comes in a strong case with a hydraulic pump, cylinder, and three arms. The settings are easy and quick to assemble from the box, and the hydraulic pump is attached directly to the cylinder, so you don't need any extra tubing.

Why Choose Orione Hydropower?

Orione Hydropower supplies different types of Hydraulic Pullers to any industry. Our goods provide a Piston plunger assembly to create enough pressure for smooth operation.

Hydraulic pullers are very popular because they are easy to use and save a lot of work. Hydraulic pullers must be checked and maintained when required to last as long as possible.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that meet or exceed our customers' anticipations is the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading manufacturer, supplier, exporter, and supplier of Hydraulic Pullers in Navi Mumbai, India. This Hydraulic Puller is available across India. Please quote here if you have this product!