- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Buy Hydraulic Tank Jack in Kuwait – Heavy-Duty Tank Lifting Solutions

As a business owner, you must be looking for some reliable ways to operate your machine or complete your daily tasks. This is where you need hydraulic equipment that can save time and ensure you get your task done on time.

Our Hydraulic Tank Jack Kuwait solutions are designed just for that. At Orione Hydropower, we provide high-quality tank lifting jacks. These pieces ensure precision and stability for every lifting project. So, whether you use them for installation or maintenance needs, we ensure that your task is complete with ease and with no issues at all.

Each tank lifting jack focuses on different needs. All these features powerful hydraulic jacking system for tanks. This system ensures an even and controlled lift. This reduces the manual labour and saves time on site. Built with heavy-duty materials, these jacks can withstand Kuwait’s tough industrial environments while delivering consistent, safe performance.

Our Hydraulic Tank Jack Kuwait range is trusted for its durable design. These all allow for better operations and management. There are no loopholes in work which ensures better results always. Also, we have trusted experts for your support.

Choose Orione Hydropower for heavy-duty tank lifting solutions that combine strength, safety, and reliability. Contact us today to find the right hydraulic jack for your tank lifting needs and experience efficient performance on every job.

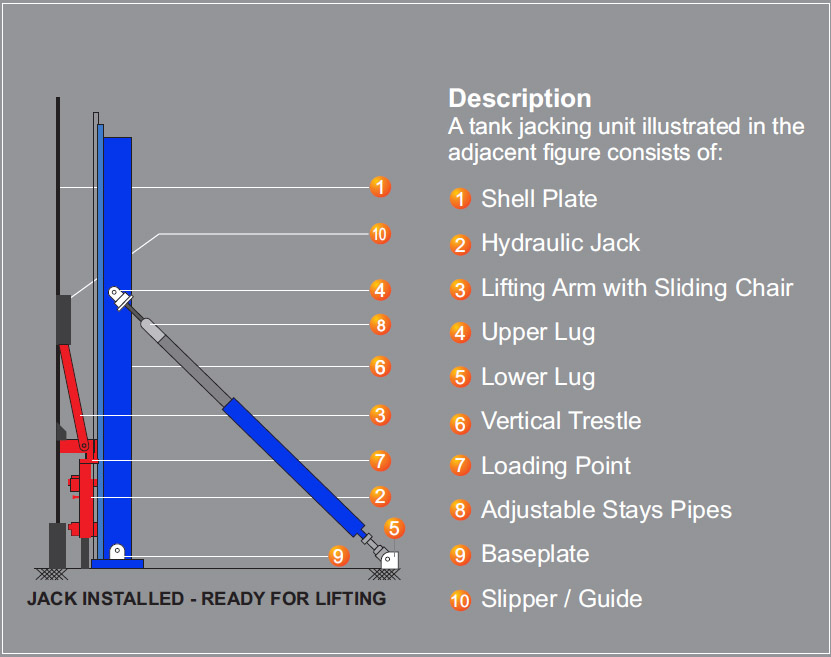

What Is a Hydraulic Tank Jack?

A Hydraulic Tank Jack is your best supporter in industrial work. It is a specialised lifting device. It is used to raise large storage tanks safely and efficiently. It is mainly during construction, maintenance, or repair. Unlike traditional mechanical lifting, a tank jacking system uses hydraulic force to provide smooth, controlled elevation.

These jacks are an essential part of any oil tank lifting system. This allows tanks to be built from the base upwards in stages.

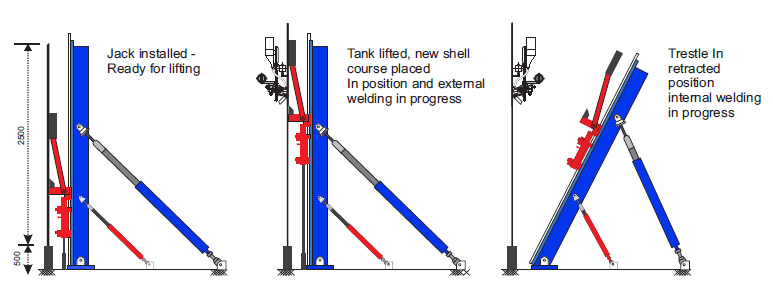

The multiple hydraulic jacks for tank erection are common. These work around the tank’s circumference. They work together to lift the tank evenly. This ensures structural integrity throughout the process. Compared to mechanical lifting vs hydraulic jacking, these offer precision. The manul labor is also low. This is why they are preferred.

The main benefits of a hydraulic tank jack are many like:

- Time savings

- Higher lifting capacities

- Minimal ground preparation

- Reduced project risks

This makes them ideal for industries that require fast, reliable tank construction and maintenance with minimal disruption to site operations.

Technical Specifications – Tank Lifting Jacks

| Description / Models | OTJ - 12 | OTJ - 18 | OTJ - 25 |

|---|---|---|---|

| Working capacity (metric tons) | 12 | 18 | 25 |

| Testing load (metric tons) | 18 | 27 | 37.5 |

| Retracting system | Single acting (spring return) / Double acting | Double acting | Double acting |

| Plate thickness range | range 6-40 mm | range( ≥8mm ) | range( ≥8mm ) |

| Arc between jacks/trestles | (1.80 up to 3.5 m) | (1.80 up to 3.5 m) | (1.80 up to 3.5 m) |

| Shell ring height width minimum | (1,800 mm) | (1,800 mm) | (1,800 mm) |

| Shell ring height maximum | (2.5 or 3.0 m) | (2.5 or 3.0 m) | (2.5 or 3.0 m) |

| Jack unitary climbs (mm/stroke) | 100 mm | 100 mm | 100 mm |

| Time per stroke | (2 to 5 minutes) | (2 to 5 minutes) | (2 to 5 minutes) |

| Jack weight approx.(kgs) | 35 | 45 | 55 |

| Trestle complete weight approx.(kgs) | 315 | 400 | 500 |

| Jack with Trestle set weight approx.(kgs) | 350 | 415 | 475 |

| Power Pack | Kgs | Liters | PSI / BAR |

| 10 HP, Max 34 jacks OTJ-12 300 kgs 150 liters 1706 psi | 300 Kgs | 150 Liter | 1706 PSI / 118 BAR |

| 15 HP, Max 45 jacks OTJ-12 300 kgs 150 liters 1706 psi | 325 Kgs | 200 Liter | 1706 PSI / 118 BAR |

| 20 HP, Max 65 jacks HLJ-12 350 kgs 300 liters 1706 psi | 350 Kgs | 350 Liter | 1706 PSI / 118 BAR |

| Retractable Jack | OTJR-12 | OTJR-18 | OTJR-25 |

Applications of Hydraulic Tank Jacks in Kuwait

Hydraulic tank jacks are quite common. These are used for tank construction Kuwait projects. These are used across various industries. Their powerful and precise lifting capabilities. This makes them a preferred choice for engineers and contractors.

Some of the key applications are:

- Petrochemical Tank Erection: It is used for vertical tanks in petrochemical plants. These jacks are safe and stable. They offer controlled lifting. All this is without requiring cranes. They allow construction teams to build tanks from the base up efficiently. This helps in maintaining structural alignment at every stage.

- Oil & Gas Industry: Hydraulic tank jacks are ideal for lifting vertical storage tanks used to store crude oil, fuel, and chemicals at refineries, terminals, and storage facilities. Their synchronised lifting system maintains tank integrity, ensuring operational safety.

- Water Treatment Facilities: These jacks help in site-built tank lifting. This is for industrial and municipal water tanks. They provide precise elevation. This is must during installation and maintenance. This helps with clean water storage and distribution.

- Chemical Plants: Hydraulic tank jacks offer secure lifting for tanks storing hazardous chemicals and process fluids. Their stable operation reduces risks. This enhances safety standards. It ensures compliance with industrial safety regulations.

- Construction Projects: Used for assembling storage tanks on construction sites, they enable bottom-up assembly without the need for heavy cranes. This reduces site congestion, manual interventions, and project costs.

Why Choose Orione Hydropower for Hydraulic Tank Jacks in Kuwait?

Reliability as a hydraulic jack supplier Kuwait is key. This is where Orione Hydropower stands out. This is mainly due to our commitment to quality, safety, and engineering excellence.

Our Orione tank lifting system is trusted by leading companies. This involve industries in the sectors like:

- Oil & gas

- Petrochemical

- Construction

- Infrastructure development

We provide:

- Precision-engineered tank jacks built from robust materials to ensure stable and safe lifting for heavy tanks in any environment.

- Credibility of a trusted jack manufacturer Kuwait. This is mainly due to many industries rely on us for projects. While this is true, we fulfill their demand for zero compromise on safety and durability.

- Customisation options tailored to your tank sizes, site conditions, and operational requirements, ensuring efficient and practical solutions for every project.

- Certified quality standards that meet international guidelines. This gives you confidence in long-term use and operational safety.

- Fast local delivery across Kuwait. This ensures that none of your work is kept on hold. All your projects go ahead without delay.

- Dedicated technical support to help you out. Be it support on which tool is best or usage, we are there for you.

Download Hydraulic Tank Jack Brochure & Datasheet

Get complete details with our Hydraulic Tank Jack Brochure and Tank Lifting Datasheet PDF to support your engineering decisions.

What’s Included:

- Full product manual with specifications and model details

- All the technical data as needed

- Installation guidelines for safe and efficient use

- Technical brochure download for all approvals

FAQs – Hydraulic Tank Jacking Systems

- 1. What is a hydraulic tank jacking system?

A hydraulic tank jacking system uses multiple hydraulic jacks. This is to lift vertical storage tanks safely. This is mainly used during construction or maintenance. It provides stable elevation without cranes. This makes it efficient for use. - 2. How many jacks are needed per tank?

The number of jacks is decided based on the diameter and weight of tank. In general, 12-24 jacks are used. All these are spaced equally around the tank. This is to ensure balanced lifting. For accurate planning, refer to our Hydraulic Tank Jacking FAQs for model-specific guidance. - 3. What safety system is included in hydraulic tank jacks?

Each jack includes a built-in safety system. There is a proper locking mechanism that helps to avoid any risks or damage. This also support long term working and helps you to boost work with safety and speed. - 4. How does synchronization work in tank lifting?

Synchronization is very crucial. It is managed via a central control unit and manifold system. This ensures all jacks lift at the same rate. This prevents tilting or structural stress and ensures smooth performance. - 5. What is the operation method for these jacks?

Hydraulic tank jacks use hydraulic circuits. The central control manages lifting and retraction. This provides smooth and precise movements. All this is with minimal manual intervention. - 6. Where can I find more tank lifting questions answered?

Check our Tank Lifting Questions section in the brochure. You can also the download the Hydraulic Tank Jacking FAQs PDF.

Get a Quote for Hydraulic Tank Jacks in Kuwait

Looking to buy hydraulic tank jacks Kuwait for your next project? We understand that this can be a tedious task. Comparing so many options and looking for the best among them is not easy. But at Orione Hydropower, we provide reliable and precision-engineered tank jacks.

Our models are tailored to your lifting needs. Request tank lifting jack price today and get competitive quotations based on your project specifications. Our team is ready to assist with model selection, technical guidance, and delivery timelines.

Enquire hydraulic jacks now to ensure safe, efficient lifting for oil, gas, water, or industrial tanks. Contact tank jack supplier Orione Hydropower and experience fast response, expert support, and trusted products designed to keep your projects on track. Click below to get your customised quote today.