- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Hydraulic Tank Jacks Suppliers in UAE – Safe & Powerful Tank Lifting Systems

Looking for trusted solutions for vertical tank erection? Hydraulic Tank Jack UAE systems are the go-to for industries handling storage tanks of massive scale. Built for precise, synchronized lifting, these Tank Lifting Jack UAE setups help raise tanks from the base, giving welders and installers 360° ground access. Traditional crane setups can be risky and slow, especially when lifting heavy storage tanks.

Hydraulic jacking system setups are widely used across petrochemical plants, refineries, and construction yards in the Middle East. This approach keeps the structure balanced, prevents side sway, and reduces stress on rank lifting systems UAE.

When projects call for both power and accuracy, many contractors turn to Industrial tank jack UAE suppliers like Technotorc and Enerpac.

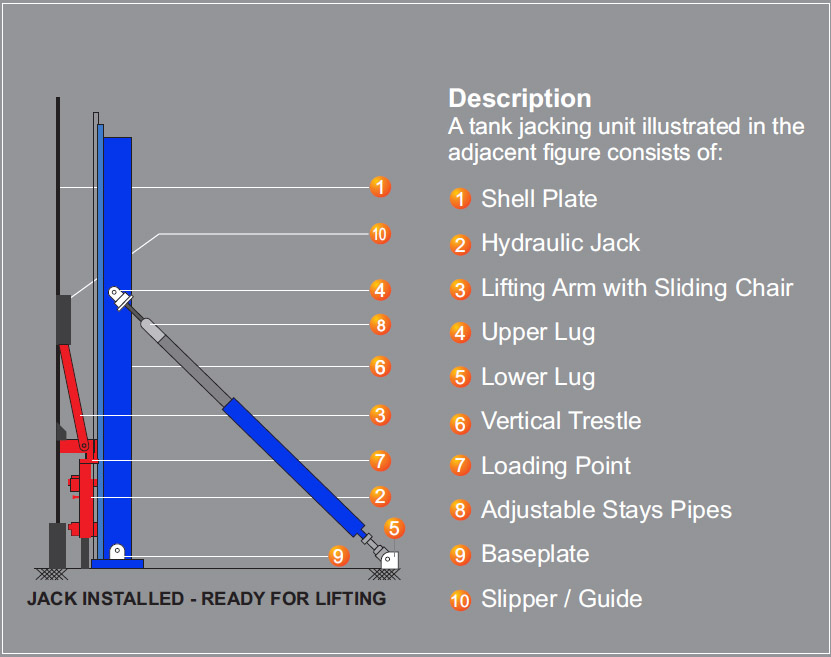

What Is a Hydraulic Tank Jack?

So, what is a Hydraulic Tank Jack and why do people use it in big projects across the UAE? But if you’re trying to lift a massive metal tank, use cranes and Tank Jacking System UAE.

A hydraulic tank erection jack keeps the work down at ground level. So welders and technicians can add tank plates, make adjustments, or do maintenance without climbing all over the structure. Much safer, and honestly, way more practical.

A complete setup includes:

- A heavy lifting jack for tanks – strong enough to raise dozens of tonnes!

- A solid tank support system – keeps everything balanced.

So, if you ever hear someone in the construction or oil & gas field mention a Tank Jacking System UAE, now you know that they’re talking about a safe way to raise tanks without relying on cranes.

Technical Specifications – Hydraulic Tank Jacks

Every tank lifting project demands equipment that can take the weight, hold position, and work in sync without second-guessing. These Hydraulic Tank Jack Specs UAE are built with numbers that talk about real capacities, true limits, and safety baked right into the hardware. Here’s what serious buyers look for.

- Load Rating per Jack

Each hydraulic jack is rated between 12 to 100 metric tonnes, depending on the application. Multiple jacks can be linked for evenly distributed lifting of tanks up to 50 meters in diameter. - Stroke Length

Every jack comes with a certain “stroke” or lifting range. Most systems have a stroke length of 100mm to 600mm, which is great for regular-sized tanks. But here’s something interesting: if the tank is taller, you can go for extended stroke jacks. - Number of Jacks in System

The number of jacks depends entirely on the size of the tank. For small jobs, a setup might use just 6 jacks. But for large tanks, it can go up to 48 or even more. So even if 20 jacks are working at once, they all lift at the same time. - System Pressure

The system operates between 180 to 300 bar of pressure. If the pressure goes too high, the system adjusts automatically so nothing gets damaged or off-track. - Safety Valves & Mechanical Locking

These release excess pressure so nothing bursts or fails. Once the tank is lifted, these lock the position so it doesn’t slip or fall, even if the system loses power or pressure. - Compatibility with Tank Shell Diameter

These systems are engineered to accommodate wide tank shell sizes, especially useful in petrochemical and terminal tank installations.

| Description / Models | OTJ - 12 | OTJ - 18 | OTJ - 25 |

|---|---|---|---|

| Working capacity (metric tons) | 12 | 18 | 25 |

| Testing load (metric tons) | 18 | 27 | 37.5 |

| Retracting system | Single acting (spring return) / Double acting | Double acting | Double acting |

| Plate thickness range | range 6-40 mm | range( ≥8mm ) | range( ≥8mm ) |

| Arc between jacks/trestles | (1.80 up to 3.5 m) | (1.80 up to 3.5 m) | (1.80 up to 3.5 m) |

| Shell ring height width minimum | (1,800 mm) | (1,800 mm) | (1,800 mm) |

| Shell ring height maximum | (2.5 or 3.0 m) | (2.5 or 3.0 m) | (2.5 or 3.0 m) |

| Jack unitary climbs (mm/stroke) | 100 mm | 100 mm | 100 mm |

| Time per stroke | (2 to 5 minutes) | (2 to 5 minutes) | (2 to 5 minutes) |

| Jack weight approx.(kgs) | 35 | 45 | 55 |

| Trestle complete weight approx.(kgs) | 315 | 400 | 500 |

| Jack with Trestle set weight approx.(kgs) | 350 | 415 | 475 |

| Power Pack | Kgs | Liters | PSI / BAR |

| 10 HP, Max 34 jacks OTJ-12 300 kgs 150 liters 1706 psi | 300 Kgs | 150 Liter | 1706 PSI / 118 BAR |

| 15 HP, Max 45 jacks OTJ-12 300 kgs 150 liters 1706 psi | 325 Kgs | 200 Liter | 1706 PSI / 118 BAR |

| 20 HP, Max 65 jacks HLJ-12 350 kgs 300 liters 1706 psi | 350 Kgs | 350 Liter | 1706 PSI / 118 BAR |

| Retractable Jack | OTJR-12 | OTJR-18 | OTJR-25 |

Applications of Hydraulic Tank Jacks in UAE Industries

Hydraulic tank lifting applications UAE are gaining ground across sectors that deal with bulk storage and heavy fabrication. From desert terminals to coastal ports, these systems are redefining how tanks are built, repaired, and expanded.

- Oil & Gas Tank Erection

Tank jacks are widely used to lift floating roof or fixed roof tanks during assembly in oil fields, terminals, and refineries across Abu Dhabi, Fujairah, and Ruwais. - Petrochemical Storage Tanks

In Sharjah and Jebel Ali zones, petrochemical players rely on hydraulic jacking systems to build large-diameter tanks for volatile chemical storage — minimizing structural strain during erection. - Maintenance Jacking Systems

For in-service tanks requiring bottom plate or ring replacement, jacks serve as safe lifting tools without full tank dismantling — saving days on project timelines. - Tank Construction UAE Projects

Along with LNG storage yards and desalination plants, contractors use tank jacks for new builds in limited-access zones where cranes are not feasible.

Why Choose Orione Hydropower for Hydraulic Tank Jacks in UAE?

- UAE-Based Local Support Team

With local stock and service hubs, Orione reduces lead times and keeps critical parts within reach across Abu Dhabi, Sharjah, and Dubai. - Built for Harsh Site Conditions

Each hydraulic lifting system UAE is tested to perform in heat, sand, and heavy-load zones. It is made for safety assurance. - Engineering Expertise That Talks Your Language

Along with tender documents and on-site training, their team supports EPCs and mechanical contractors throughout the project life cycle. - Safety-First System Design

Redundant locking collars, pressure control, and multi-jack sync setups bring peace of mind on-site. It is vital when lifting hundreds of tonnes.

For those looking for more than a product brochure, Orione stands out as a trusted tank jack supplier UAE with skin in the game.

Download Datasheet – Hydraulic Tank Jack

Need solid numbers before making a call? Get the full Tank Jack Datasheet UAE with all system specs, load charts, jack dimensions, and pressure ratings. This Hydraulic Jack PDF UAE is perfect for engineering reviews, tenders, or on-site planning.

Includes:

- Download tank jack specs

- System layout drawings

- Cylinder stroke charts

- Safety lock mechanisms

- Site handling instructions

- Hydraulic jack manual

Grab the technical brochure now, built for teams who like having the full picture before site deployment. We offer downloadable materials for technical review.

FAQs – Hydraulic Tank Jacking System

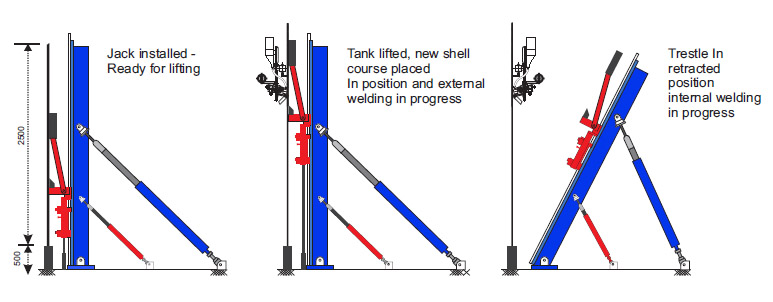

- How does a hydraulic tank jack work?

The system lifts the tank from the base, section by section, using synchronized hydraulic cylinders. Each jack is placed under a vertical column attached to the tank wall. As pressure builds, the jack pushes up the entire tank shell, allowing crews to weld new rings underneath. - Is load evenly shared between jacks?

Yes. Load distribution is controlled through a centralized hydraulic panel. This equal pressure feed prevents tilting, which is critical for tall or wide tanks. It is the most common tank jacking FAQ UAE. - Can the system be controlled remotely?

Absolutely. Most units are designed for remote control lifting from a safe distance, helping reduce worker exposure during operation. - What safety measures are included?

Each jack has safety interlocks, mechanical locks, and pressure relief valves to prevent unintentional drops. These are standard features, not add-ons. - How long does it take to erect a tank using this method?

Tank erection time depends on the tank size and the number of jacks used. On average, medium-sized tanks can be lifted and completed within 10–15 days with 12–24 jacks in operation.

Request a Quote – Hydraulic Tank Jack UAE

Looking to buy tank jack UAE for your next tank erection or repair job? Orione Hydropower supplies proven lifting systems built for on-site durability across UAE’s toughest job sites.

- Send your hydraulic tank jack quote UAE request with tank size, lifting height, and location. Also, request pricing with technical suggestions.

- Quick replies for any industrial jack inquiry

- Custom kits based on load, stroke & terrain

- Trusted UAE tank lifting system supplier with ready stock

Use the form or email your specs to support — it’s just one message away.