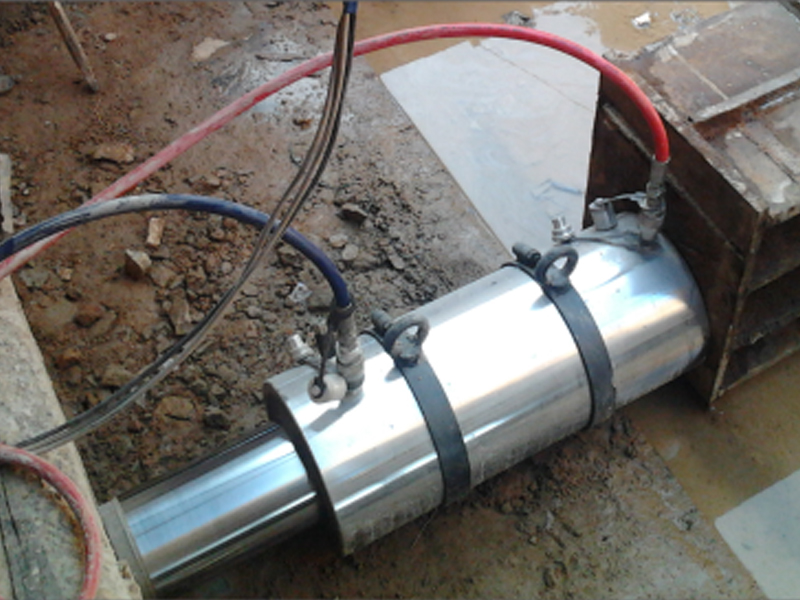

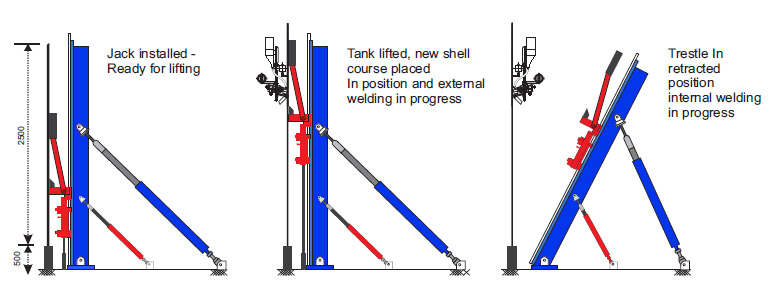

- Hydraulic Tank Jack

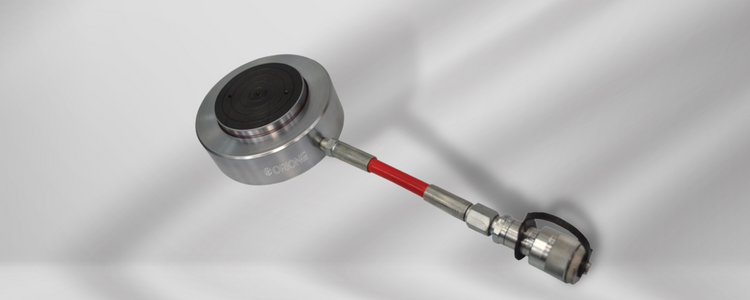

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

General Purpose Jacks - Plain Ram, Double Acting, Oil Return

General purpose jacks are hydraulic devices that can be used for lifting, pushing, pulling, or holding loads in various applications. They consist of a cylinder, a piston, a pump, and a valve that controls the flow of hydraulic fluid. Double-acting jacks have two ports for fluid inlet and outlet, which allow them to extend and retract the piston with hydraulic pressure.

General purpose jacks double acting are robust and reliable tools that can help you with various tasks involving lifting or moving heavy objects. However, you should always follow the manufacturer's instructions and safety precautions when using them.

Orione Hydropower is a leading manufacturer and supplier of General Purpose Jacks Double Acting in Navi Mumbai, Maharashtra, India. Our high-end designs are made of metal to prevent corrosion and withstand wear. As a trusted manufacturer in Navi Mumbai, we use only the finest quality materials to deliver the best options to our customers. Please browse our website and place your order according to your preferences.

| Capacity (ton) |

Capacity (kN) |

Stroke (mm) |

Model | Effective area (cm2) |

Oil cap. (cc) |

Closed height (mm) |

Wt. (Approx.) (kg) |

|---|---|---|---|---|---|---|---|

| 10 | 111 | 150 | ODP 10-150 | 15.9 | 239 | 275 | 8 |

| 15 | 167 | 150 | ODP 15-150 | 23.8 | 356 | 280 | 10.5 |

| 20 | 218 | 150 | ODP 20-150 | 31.2 | 468 | 285 | 14.2 |

| 25 | 270 | 150 | ODP 25-150 | 38.5 | 577 | 295 | 14 |

| 30 | 309 | 150 | ODP 30-150 | 44.2 | 663 | 305 | 16 |

| 50 | 550 | 150 | ODP 50-150 | 78.5 | 1178 | 305 | 25.5 |

| 75 | 792 | 150 | ODP 75-150 | 113.1 | 1696 | 305 | 36.5 |

| 100 | 1077 | 150 | ODP 100-150 | 153.9 | 2309 | 310 | 52.5 |

| 150 | 1589 | 150 | ODP 150-150 | 227 | 3405 | 320 | 83 |

| 200 | 2199 | 150 | ODP 200-150 | 314.2 | 4712 | 345 | 114 |

| 250 | 2661 | 150 | ODP 250-150 | 380.1 | 5702 | 350 | 145.5 |

| 300 | 3167 | 150 | ODP 300-150 | 452.4 | 6786 | 365 | 179 |

| 400 | 4008 | 150 | ODP 400-150 | 572.6 | 8588 | 385 | 257 |

| 500 | 4948 | 150 | - | 706.9 | 10603 | - | - |

| 600 | 5987 | 150 | - | 855.3 | 12829 | - | - |

| 800 | 7939 | 150 | - | 1134.1 | 17012 | - | - |

| 1000 | 9930 | 150 | - | 1418.6 | 21279 | - | - |

| 1500 | 15154 | 150 | - | 2164.8 | 32472 | - | - |

| 2000 | 20458 | 150 | - | 2922.5 | 43837 | - | - |

| Capacity (ton) |

Capacity (kN) |

Stroke (mm) |

Model | Effective area (cm2) |

Oil cap. (cc) |

Closed height (mm) |

Wt. (Approx.) (kg) |

|---|---|---|---|---|---|---|---|

| 10 | 111 | 150 | ODPS 10-150 | 15.9 | 239 | 285 | 8.2 |

| 15 | 167 | 150 | ODPS 15-150 | 23.8 | 356 | 290 | 10.7 |

| 20 | 218 | 150 | ODPS 20-150 | 31.2 | 468 | 300 | 14.5 |

| 25 | 270 | 150 | ODPS-25-150 | 38.5 | 577 | 310 | 14.3 |

| 30 | 309 | 150 | ODPS 30-150 | 44.2 | 663 | 320 | 16.5 |

| 50 | 550 | 150 | ODPS 50-150 | 78.5 | 1178 | 320 | 26.5 |

| 75 | 792 | 150 | ODPS 75-150 | 113.1 | 1696 | 330 | 37.5 |

| 100 | 1077 | 150 | ODPS 100-150 | 153.9 | 2309 | 330 | 54 |

| 150 | 1589 | 150 | ODPS 150-150 | 227 | 3405 | 345 | 85.5 |

| 200 | 2199 | 150 | ODPS 200-150 | 314.2 | 4712 | 370 | 117.5 |

| 250 | 2661 | 150 | ODPS 250-150 | 380.1 | 5702 | 385 | 150.5 |

| 300 | 3167 | 150 | ODPS 300-150 | 452.4 | 6786 | 400 | 188 |

| 400 | 4008 | 150 | ODPS 400-150 | 572.6 | 8588 | 425 | 268 |

| 500 | 4948 | 150 | ODPS 500-150 | 706.9 | 10603 | 450 | 365 |

| 600 | 5987 | 150 | ODPS 600-150 | 855.3 | 12829 | 480 | 450 |

| 800 | 7939 | 150 | ODPS 800-150 | 1134.1 | 17012 | 515 | 645 |

| 1000 | 9930 | 150 | ODPS 1000-150 | 1418.6 | 21279 | 560 | 868 |

| 1500 | 15154 | 150 | ODPS 1500-150 | 2164.8 | 32472 | 620 | 1534 |

| 2000 | 20458 | 150 | ODPS 2000-150 | 2922.5 | 43837 | 705 | 2357 |

Features of General Purpose Jacks Double Acting

Some features that make these jacks ideal for these applications are:

Sustained load holding with lock nut in the vertical and horizontal direction. It means that the jack can maintain its position without relying on hydraulic pressure once the load is lifted or pushed to the desired level. The lock nut also prevents accidental lowering or retraction of the ram due to leakage or failure of a hydraulic system.

Fast and complete ram retraction. It means that the jack can return to its original position quickly and easily by reversing the hydraulic pressure. It reduces the cycle time and increases the efficiency of operation.

Spherical saddle for 500t and above; optional for lower capacities. It means that the jack has a curved surface at the end of its ram that allows it to adapt to uneven or angled surfaces. It reduces the risk of damage or slippage of the load due to misalignment or instability.

Suited for construction and heavy industries. It means that these jacks are made of high-quality alloy steel with corrosion-resistant coating. They also have dust seals and wipers to protect them from dirt and debris. They can withstand harsh environments and heavy-duty usage.

Applications of General Purpose Jacks Double Acting

General purpose jacks double acting are hydraulic jacks that can extend and retract their rams by applying hydraulic pressure in both directions. They are universal devices used for various lifting and push-pull applications in different industries. This information will explain to you some of the standard applications of these jacks and their advantages over other types of jacks.

These jacks are designed to suit most of the general lifting and push-pull applications, such as:

Advantages of General Purpose Jacks Double Acting

One of the advantages of double acting jacks is that they can achieve faster and more complete ram retraction than single acting jacks, which rely on gravity or external force to return the piston. Another advantage is that they can sustain load holding in both vertical and horizontal directions with a lock nut mechanism. It makes them suitable for construction and heavy industries where stability and safety are essential.

Some of the advantages of general purpose jacks double acting are:

Types of General Purpose Jacks Double Acting

Different types of double-acting jacks are available in the market, depending on their design features and specifications. Some of the common types are:

Plain Ram Double Acting Jacks

These jacks have a smooth cylindrical piston without any threads or attachments. They are simple, versatile, and can be used for most general lifting and push-pull applications.

Threaded Ram Double Acting Jacks

These jacks have a threaded piston that can be attached to various accessories such as eye bolts, clevises, or spherical saddles. They offer more flexibility and alignment options for different load configurations.

Hollow Ram Double Acting Jacks

These jacks have a hollow piston that allows a rod or cable to pass through them. They are ideal for pulling or tensioning applications where space is limited.

How to Select the best General Purpose Jacks Double Acting

The capacity, stroke length, working pressure, and oil capacity of double acting jacks vary depending on their size and model. The accommodation ranges from 10 to 1000 tons, the stroke length ranges from 150 to 300 mm, the working pressure ranges from 700 to 1000 bar, and the oil capacity ranges from 0.25 liter to 15 liters. The jacks weight also depends on its dimensions and material, which can be alloy or stainless steel

When choosing a double acting jack for your application, you should consider several factors, such as:

You should also consult an expert or manufacturer before selecting a jack to ensure compatibility with your system components such as hoses, fittings, pumps, etc.

How to Maintain General Purpose Jacks Double Acting

Double acting jacks are potent tools that can help you perform various tasks efficiently and safely. However, they also require proper maintenance and care to ensure optimal performance and longevity. You should follow these tips to keep your jack in good condition:

Why Choose Orione Hydropower?

General purpose jacks double acting are also known as oil return jacks or bi-directional jacks. They have a plain or threaded ram that can move in both directions by changing the direction of the hydraulic fluid flow. They have a maximum working pressure of 700 bar and a capacity range from 10 to 1000 tons. They also have a standard stroke length of 150 mm, but some models can have longer strokes, up to 300 mm.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfill or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and trader of Low Height Jacks Single Acting in Navi Mumbai, India. This hydraulic jack is available across India. Please quote here if you have this product!