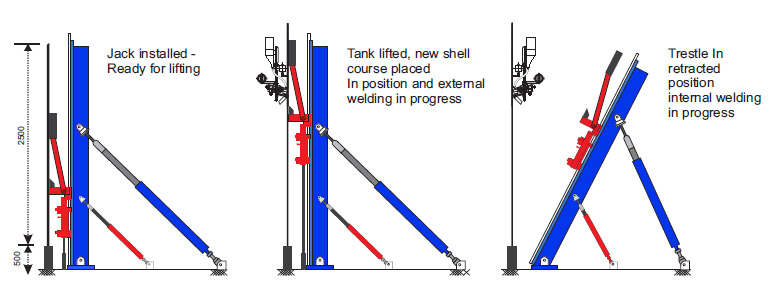

- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Hydraulic Presses Suppliers

Do you want high-quality Hydraulic Presses at an affordable price? You arrive at the right place. We are the best manufacturers and suppliers of Hydraulic Presses in India.

This information will explain more about Our Hydraulic Presses.

Continue reading further below.

Introduction

The hydraulic press is always in high demand across many sectors. They enable users to fit, assemble and bend sheet metals, bearings, and other machine parts. Hydraulic presses use pump-generated pressure to compress steel cylinders into metals.

What is a Hydraulic Press?

A hydraulic press is a mechanical machine that shapes and deforms metals by transferring energy through the liquid. It is based on Pascal's principle. The gadget is primarily used to increase the application of lesser forces. According to Pascal's guide, pressure strength in a static fluid is transferred equally in all directions.

The Hydraulic press comprises the framework, the power system, and the hydraulic control system. A pump applies pressure to a liquid, resulting in mechanical force.

Features of Hydraulic Presses

Hydraulic presses operate according to Pascal's law.

Every hydraulic press has a piston that operates like a pump, delivering a tiny mechanical force in a relatively small area.

On the other hand, a hydraulic press's wide area piston creates more mechanical force.

Hydraulic presses always deliver a total power stroke.

Note: We are the best Hydraulic Presses Manufacturers and Suppliers in Navi Mumbai, India. We offer Hydraulic Presses at lowest price.

Advantages of Hydraulic Press

Compared to the manual machine, the hydraulic press machine is lower in weight and has fewer parts for producing sheet metal shapes.

The following are the primary benefits of hydraulic press machines:

A Disadvantage of Hydraulic Press

Types of Hydraulic Presses

Hydraulic presses are classified into four types based on their designs, which are as follows:

Applications of a Hydraulic Presses

Hydraulic presses have traditionally been utilized in the following industries and machinery.

We have explained some uses of Hydraulic Press Below:

Manufacturing

The most general applications for hydraulic presses are part production and fabrication. Because of the speed with which hydraulic presses can design and shape vehicle parts ranging from windshields to gear housings, they have become an indispensable part of product manufacture. Hydraulic presses are used in various sectors, from steel manufacture and installation to precise and complicated electronics components.

Powder Compacting

A powder compacting press compresses diverse powdery materials into forms, patterns, and thicknesses by putting a unique force on the material in a mold. Any of the many hydraulic presses, from two columns to four columns, can be utilized for the process.

The powder combination is put into a steel die and pressured to the shape and form of the dice to complete the compacting process. The three stages of the compression process distort the powder particles and greatly enhance their density.

Scrap Baling

The scrap baling press, which shreds vehicles, machinery, and equipment, has gained popularity in entertainment. This hydraulic press has grown in favor of recycling and repurposing raw materials from obsolete items.

A hydraulic scrap baler uses cold pressing to compress different metals kinds for simple storage, processing, and transportation. Various types of scrap balers are designed to break down and compact a particular material.

Ceramics Production

Ceramics are traditionally formed and shaped using a hot kiln fired to temperatures above 1800° F. Hydraulic presses that operate at ambient temperature gradually replace heated presses. Hydraulic presses compress form of carbon into shapes and forms like bathroom tiles, brickwork, and cement with the slightest pressure and the quickest amount of time.

Laboratory

Laboratory presses are employed in the creation and manufacture of new products, as well as in the quality control of existing parts. Manufacturers use laboratory presses to test their manufacturing techniques and efficiency during product development. Although most laboratory presses are lightweight and compact, they may execute all of the activities of a hydraulic production press to offer data and performance parameters.

Military

An essential military hydraulic press is employed to load shells and other munitions. Additional uses include fuel cell compression and the manufacture of rails and tires. Help in military production necessitates precisely defined metal-formed pieces with precise dimensions and tolerances. Hydraulic presses are also used to make military parts comply with requirements for minimal differences in both performance and quality.

Concrete Testing

Concrete is widely used in construction to create buildings, warehouses, and industrial plants. Concrete manufacturers use hydraulic presses to test set cement's tensile strength and behavior. The tests provide information on preset tension softening. The data collected is utilized to fine-tune the concrete mixture to fulfill the required specifications.

Working of Hydraulic Press

Typically, many little rams are utilized rather than one giant ram since the thrust forces are more accessible to control than large quantities. The working load determines the number of rams. The ram is propelled by hydraulic pressure. A pump and a hydraulic accumulator supply the high-pressure liquid. The hydraulic accumulator functions as a link between the pump and the rams. A hydraulic accumulator holds the high-pressure liquid when the press is static. A hydraulic press is employed when a strong force is required for operation.

Hydraulic Press Processes

When a hydraulic press is utilized for slicing, bending, shaping, drawing, punching, coining, or puncturing a workpiece, it transforms into a method of forging the workpiece by employing a die with an upper and lower half that is the shape and form of the item to be made. The workpiece is put on the die's lower half, and the ram lowers the upper half to squeeze the workpiece into the required shape.

Blanking

Blanking is cutting a form or shape from a metal coil, sheet, strip, or billet. The chopped shape is forwarded for further processing. The most typical blanking method is to feed a metal coil into a hydraulic press.

Drawing

Metal drawing compresses a workpiece by lowering its cross-section with a reduced cross-sectional area mold or die. In the drawing process, the workpiece is dragged through the die instead of being forced through it during extrusion. Completing the drawing may necessitate a force of up to 150 tons.

Piercing

Piercing is a sheet metal punching used to produce shapes from metal sheets. Piercing is a broad phrase that refers to the cutting, punching, and shearing apertures in a workpiece. Piercings are the inverse of blanking, which may include holes, slits, slots, or any other shape. The workpiece is the piece that is carved out during the blanking process. The portion of the piercing that is taken off is called scrap.

Stretching

Stretch forming is a metal shaping process that involves stretching and bending a piece of sheet metal over a die to create a big, curved object. A carriage propelled by hydraulic force grips the workpiece on its edges. The forming block is a formation die that is pressed against the workpiece. Stretching is often done using a vertical hydraulic press to lower the thickness of the workpiece.

Straightening

Straightening is used to straighten bent or broken shafts or sheet metal. The repair releases the stress on the shaft that leads it to be distorted in an effective straightening process. Numerous hydraulic straighteners are available, each tailored to the sort of workpiece to be straight.

One type of hydraulic straightening press features a big table on which the press applies pressure to a curved or spiral metal plate. The straightened shaft, tube, or pipe is mounted on conveyor-like rollers, pushed into the hydraulic press, or set on a platform where the press molds it.

Folding

A hydraulic folding machine supports the workpiece and exerts pressure on the center of the workpiece to rotate the flanges upward. A hydraulic press's method and design simplify folding multiple pieces and huge sections.

Compared to the press brake method, the advantages of the hydraulic folding process include lower risk and less surface damage to the workpiece.

Coining

Coining, also called minting, is a closed die operation that fills the form and profile of the die with a metal workpiece. The applied load compresses the workpiece and shifts its thickness as it is pressed between the halves of the dice, shaping it to the die design. The key to producing a detailed surface with properly formed edges and corners is a deliberate and constant application of force.

Stamping

Stamping is a broad phrase that refers to a range of manufacturing methods that employ a hydraulic press to generate static pressure to manufacture finite and precise components and parts. Because of its precision and ability to manufacture sophisticated and complex configurations, hydraulic presses are utilized for stamping. Hydraulic presses offer a highly versatile and adaptive stamping technology since the stroke can be altered and the pressure exerted controlled.

Which Types Of Hydraulic Presses Do We Provide?

Orione Hydropower manufactures and supplies a wide range of hydraulic presses with varying structures to fulfill the unique needs of modern businesses.

Conclusion

A hydraulic press is mechanical equipment that shapes, deforms, and configures various metals, plastics, rubber, and wood using the static pressure of a liquid as specified by Pascal's principle.

The passage of fluids between the two pistons generates increasing pressure, which produces mechanical force to move the anvil of a hydraulic press downward into a workpiece that has been contorted to the required shape.

The differences between hydraulic presses are due to various things, including their frame and the metals utilized to make them.

Hydraulic presses are integral to modern industrial activities, from shaping and producing machine parts to crushing and compacting garbage and refuse.

Why Choose Orione Hydropower?

Our Orione Hydropower and its team are experts in supplying hydraulic equipment and solutions for various industrial applications. Visit our website for more information.

Since its inception, Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of hydraulic jacks, hydraulic systems, hydraulic presses, and elements for almost all industries, including Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM suppliers.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that satisfy or surpass our customer's expectations is the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading manufacturer of Hydraulic Presses, Hydraulic Presses suppliers, Hydraulic Presses exporters, and Hydraulic Presses in Navi Mumbai, India. These Hydraulic Presses are available throughout India. Please quote here if you have this product!