- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Hydraulic Tank Jacking Equipment Suppliers

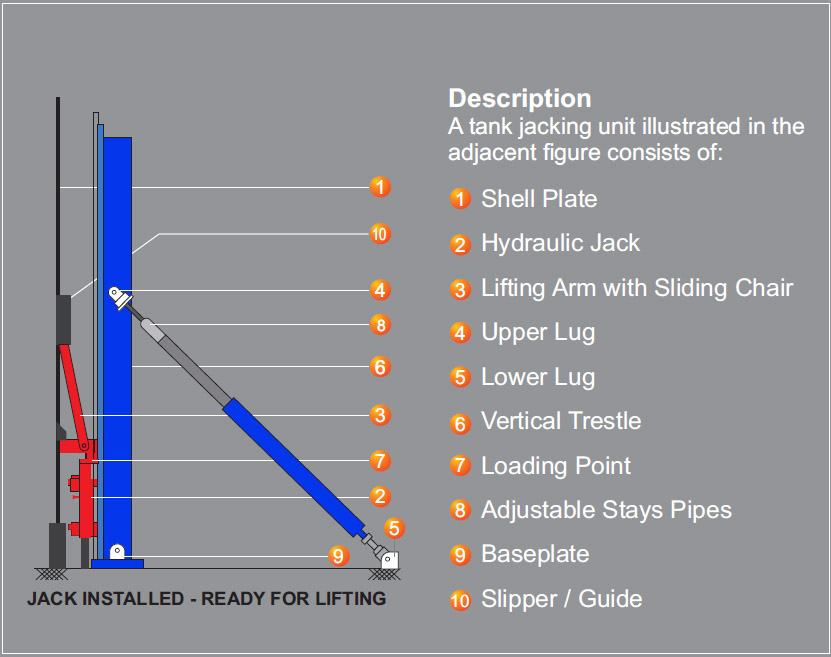

A hydraulic tank jack is used to lift and erect storage tanks of different sizes and shapes. It is also known as a hydraulic tank jacking system or tank lift jack. Hydraulic tank jack can be used for welded and bolted tanks, offering many advantages over conventional tank construction methods.

Hydraulic tank jacks have two main parts: a hydraulic pump and a set of jacking units. The hydraulic pump provides pressurized fluid to the jacking units, which are attached to the tank or cylinder at different points. The jacking units consist of a piston and a cylinder that can extend or retract depending on the direction of fluid flow; by synchronizing the movement of multiple jacking units, the tank or cylinder can be lifted or lowered with precision and safety.

Orione Hydropower is a leading manufacturer and supplier of Hydraulic Tank Jack in Navi Mumbai, Maharashtra, India. Our high-end designs are made of metal to prevent corrosion and withstand wear. As a trusted manufacturer in Navi Mumbai, we use only the finest quality materials to deliver the best options to our customers. Please browse our website and place your order according to your preferences.

| Description / Models | OTJ - 12 | OTJ - 18 | OTJ - 25 |

|---|---|---|---|

| Working capacity (metric tons) | 12 | 18 | 25 |

| Testing load (metric tons) | 18 | 27 | 37.5 |

| Retracting system | Single acting (spring return) / Double acting | Double acting | Double acting |

| Plate thickness range | range 6-40 mm | range( ≥8mm ) | range( ≥8mm ) |

| Arc between jacks/trestles | (1.80 up to 3.5 m) | (1.80 up to 3.5 m) | (1.80 up to 3.5 m) |

| Shell ring height width minimum | (1,800 mm) | (1,800 mm) | (1,800 mm) |

| Shell ring height maximum | (2.5 or 3.0 m) | (2.5 or 3.0 m) | (2.5 or 3.0 m) |

| Jack unitary climbs (mm/stroke) | 100 mm | 100 mm | 100 mm |

| Time per stroke | (2 to 5 minutes) | (2 to 5 minutes) | (2 to 5 minutes) |

| Jack weight approx.(kgs) | 35 | 45 | 55 |

| Trestle complete weight approx.(kgs) | 315 | 400 | 500 |

| Jack with Trestle set weight approx.(kgs) | 350 | 415 | 475 |

| Power Pack | Kgs | Liters | PSI / BAR |

| 10 HP, Max 34 jacks OTJ-12 300 kgs 150 liters 1706 psi | 300 Kgs | 150 Liter | 1706 PSI / 118 BAR |

| 15 HP, Max 45 jacks OTJ-12 300 kgs 150 liters 1706 psi | 325 Kgs | 200 Liter | 1706 PSI / 118 BAR |

| 20 HP, Max 65 jacks HLJ-12 350 kgs 300 liters 1706 psi | 350 Kgs | 350 Liter | 1706 PSI / 118 BAR |

| Retractable Jack | OTJR-12 | OTJR-18 | OTJR-25 |

Advantages of a Hydraulic Tank Jacks

Hydraulic tank jack offers many benefits over conventional tank construction methods such as crane erection or scaffolding erection. Some of these benefits are:

Safety: Hydraulic tank jack reduces the risk of accidents and injuries during tank construction as it eliminates working at heights, heavy lifting and manual handling.

Speed: Hydraulic tank jack increases productivity and efficiency by reducing construction time by up to 50%. It also allows simultaneous welding or bolting while lifting, which saves more time.

Quality: Hydraulic tank jack improves quality control by ensuring uniformity and accuracy in each course's alignment, levelness and roundness.

Cost: Hydraulic tank jack reduces labour costs as it requires fewer workers and less supervision. It also reduces material costs as it minimizes wastage and rework.

Flexibility: Hydraulic tank jack can handle different types of tanks with different capacities, weights, diameters and heights. It can also adapt to various site conditions, such as uneven ground, limited space or windy weather.

Applications of Hydraulic Tank Jacks

Hydraulic tank jacks have many applications in different industries where heavy tanks or cylinders need to be lifted or lowered for various purposes. Some examples are:

Construction: Hydraulic tank jacks can erect steel tanks for water storage, fire protection, sewage treatment, etc. They can also be used to install concrete pipes for drainage systems.

Shipbuilding: Hydraulic tank jacks can lift and lower ship sections during fabrication or repair. They can also be used to launch ships from dry docks into the water.

Mining: Hydraulic tank jacks can be used to raise and lower mining equipment such as crushers, conveyors, mills, etc. They can also be used to transport ore containers from underground mines to the surface.

Oil and gas: Hydraulic tank jacks can be used to lift and lower oil storage tanks during installation or maintenance. They can also be used to position pipelines for oil and gas transportation.

How Does The Hydraulic Tank Jacks Work?

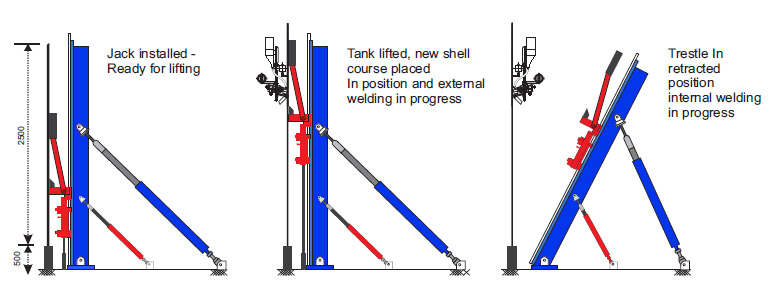

Hydraulic tank jack works by using dual-stage hydraulic cylinders attached to the top edge of the tank shell. The cylinders are connected to a hydraulic power pack that provides the required pressure and oil flow to lift the tank shell. The lifting process is controlled by a central panel that monitors each cylinder's pressure, height and alignment.

The lifting process starts by placing the bottom course of the tank shell on a temporary support structure, such as wooden blocks or steel beams. Then, the hydraulic cylinders are fixed to the top edge of the surface using clamps or brackets. The hydraulic power pack is activated, and the cylinders lift the shell gradually until it reaches a certain height.

At this point, the second course of the tank shell is welded or bolted to the first one from the inside. The welding or bolting can be done manually or automatically using various methods such as submerged arc welding (SAW), gas metal arc welding (GMAW) or gas tungsten arc welding (GTAW). The welding or bolting can also be done simultaneously with lifting using synchronized jacks.

After completing the second course, the lifting process resumes until another height is reached. Then, the third course is added until all procedures are completed. The final system may require some adjustments to fit with the roof structure.

The lowering process is similar to lifting but in reverse order. The hydraulic power pack releases oil from each cylinder gradually until it reaches its original position. The temporary support structure is removed, and the tank is ready.

Why Choose Orione Hydropower?

A hydraulic tank jack is equipment that uses dual-stage hydraulic cylinders to lift and erect storage tanks from the top down. It offers many advantages over conventional methods, such as safety, speed, quality, cost and flexibility. We provide Hydraulic jacks with customized solutions according to your needs and specifications.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfil or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and trader of Hydraulic tank jacks in Navi Mumbai, India. This Hydraulic tank jack is available across India. Please quote here if you have this product!