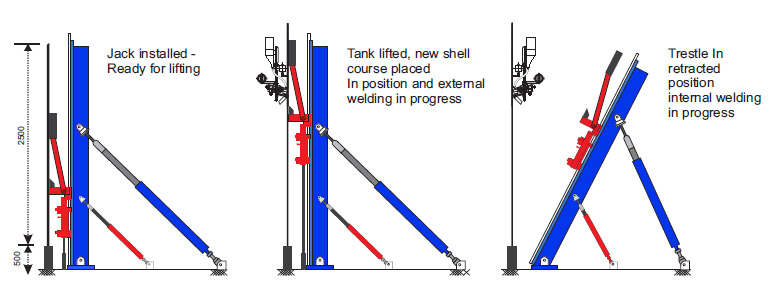

- Hydraulic Tank Jack

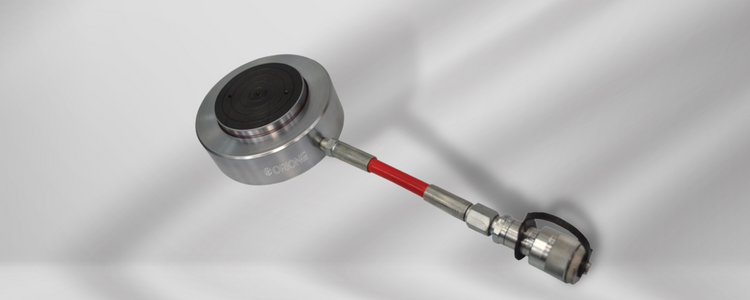

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Hydraulic Torque Wrench Suppliers

Do you want high-quality Hydraulic Torque Wrench at an affordable price? You arrive at the right place. We are the best manufacturers and suppliers of Hydraulic Torque Wrench in India.

This information will explain more about OurHydraulic Torque Wrenches.

Continue reading further below.

Introduction

For a long time, several industries have relied heavily on hydraulic wrenches as a tool. A hydraulic torque wrench is a calibrated machine that measures the torque exerted to achieve and tighten the desired tightness and loosen any screw. Hydraulic wrenches are ideal for any sector that requires an effective system for tight nuts.

What Are Hydraulic Torque Wrenches?

Hydraulic torque wrenches are professional tools used to tighten fasteners of different sizes in a controlled way for industrial applications. It is a portable torque wrench that has been improved. A hydraulic torque wrench is an electric tool that uses hydraulics to give a fastener the right amount of torque to tighten or loosen it.

A torque wrench pulls the nut with an impact socket with or without another tool. Hydraulic torque wrenches apply a controlled amount of torque to an appropriately greased fastener. They work in many fields, such as transportation, field construction, and the search for oil and gas. Hydraulic torque wrenches are employed with bolts or fasteners that are well-oiled

Hydraulic torque wrenches are smaller and quieter than pneumatic torque wrenches. They are also lighter. These wrenches are accurate to 3% and will last a long time. They are also used in industries and situations where large bolts need to be tightened to a precise level.

Features / Benefits of Hydraulic Torque Wrenches

The hydraulic torque wrench has the following features or advantages:

Types of Hydraulic Torque Wrench

There are two kinds of hydraulic torque wrenches, each with different uses.

Square Drive Hydraulic Torque Wrenches

The square drive hydraulic torque wrench is a type of hydraulic Wrench. Its driving shaft turns the impact socket to pre-tighten the nut and is usually used to tighten and loosen bolts bigger than one inch. It is also used with high-strength sockets to tighten or loosen bolts of different sizes within a safe torque range. The square-drive hydraulic Wrench is used for a broader range of things than the low-profile hydraulic torque wrench.

The one-piece fuselage could make the fuselage much more robust and last longer. It lasts longer, is stronger and lighter, and can be matched to different working heads with just one powerhead. Because 360° x 180° rotating tubing couplings are used, there are no limits on the space used. With the easy-to-press trigger-style lock, you can put the 360° fine-tuning reaction arm on a stable fulcrum. Each stroke moves quickly and turns 27 degrees.

When you use a precise ratchet, you can be as accurate as 3% of the time. Moving around in tight spaces is easy because the nose isn't too big—surface treatment to stop corrosion that can be used in harsh conditions. There are many different sizes of square-drive wrenches. All of the items are made from aluminum-titanium alloy and high-strength alloy steel.

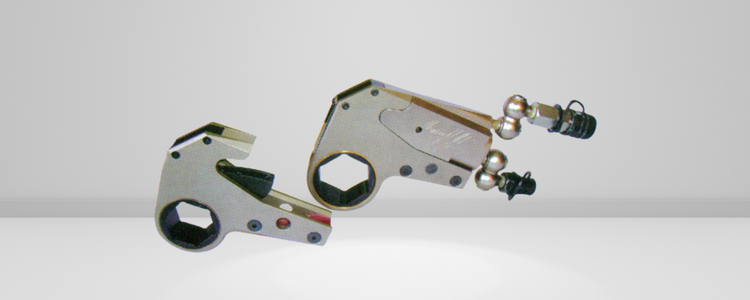

Low Profile Hydraulic Torque Wrenches

Its drive shaft turns the socket to pre-tighten the nut. This tool is usually used to tighten and loosen bolts with a diameter of more than 1 inch (Reducers can be used for smaller bolts). It is generally used when there is little room to work when there are double nuts, small bolts, or nuts that are too close to something else. Our open hydraulic torque wrenches can be made to meet most engineering needs. All of the products are made from aluminum-titanium alloy and high-strength alloy steel. They are strong, tough, thin, double-acting, fast, and have a big corner.

The maximum operating pressure of a low-profile hydraulic torque wrench is 70 MPa, and the torque repeatability is 3%. The hose attachment that can turn 360° is excellent for tight spaces and is easy to move. The low-profile hydraulic Wrench is vital because it is made well.

Note: We are the best Hydraulic Torque Wrench Manufacturers, Suppliers and Traders in Navi Mumbai, Maharashtra, India. We offer Hydraulic Torque Wrench to our consumers at a lower price.

Hydraulic Torque Wrenches Applications

A hydraulic torque wrench is essential for a variety of large bolts in a variety of industries. The following are a few examples of such sectors:

Generally, a hydraulic wrench is used in all installation and disassembly-related tasks and tools requiring precise torque measurement.

How to Use a Hydraulic Torque Wrench?

Connect the Parts

We started by connecting the power pack to one end of the hose and the Wrench to the other. After that, check again to ensure all connections are tight and all parts are connected.

Adjusting the Settings

With the new settings on your hydraulic torque wrench, you can set the correct torque levels for your project. If the task requires a certain amount of torque, stick to it. If you don't have a torque setting, start with the lowest and work your way up, careful not to overtighten any fasteners.

Starting to make use of the Wrench

Start by tightening the nut with the torque wrench. If a gasket is needed, ensure it is in the right place. The twist will have a big hole resembling a nut or hex bolt on one side. Before you use it, make sure you fully understand the instructions. Next, try turning on the torque wrench and wait until the desired torque level is reached. The twist will stop when this level is gone; you can remove it.

Working of the Hydraulic Torque Wrench

It is important to remember that the hydraulic torque wrench is based on Newton's Law, which states that for every force applied, an equal and opposite force is applied back to it. When you turn a nut or bolt counterclockwise, you create tension in the opposite direction. It functions as a clamping force, drawing the parts together under a specific load or pressure in the same order. As the torque increases, the joint loses strength, and the nut or bolt can move.

The torque needed to tighten or loosen a joint depends on its length, size, and type, the quality of the fastener, and the lubricant utilized.

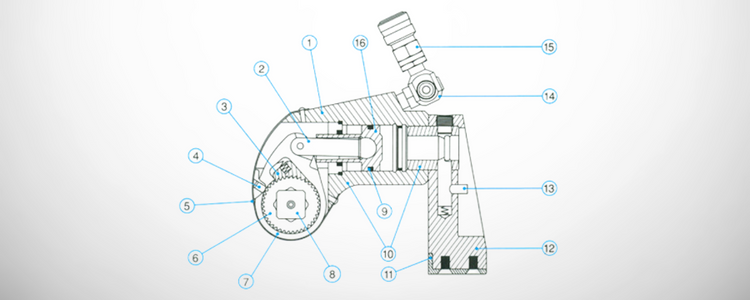

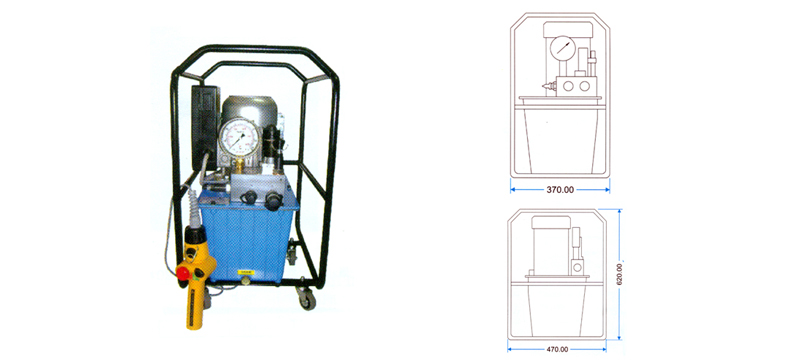

An electric hydraulic pump transfers energy from the power source to the hydraulic Wrench via dual high-pressure tubes. When the internal motor is turned on, it produces pressure. The hydraulic oil is transmitted from the interior to the hydraulic Wrench via the tubing medium. The piston rod of the hydraulic Wrench is pushed, pushing the front portion of the twist. Finally, the ratchet wheel can move the driveshaft to accomplish the bolt pre-tightening.

Electric hydraulic pumps are one of the things that help make hydraulic wrenches work, along with things like electric solenoid valve drives or compressed air pushes (pneumatic).

The working head of the hydraulic Wrench is made up of three main parts:

The cylinder output force, piston rod, and transmission parts make up a pair of motions. A hydraulic wrench has a magnifying arm that measures the distance between the center of the cylinder and the center of the transmission part. So, a hydraulic wrench's theoretical output torque equals the cylinder's output force times the force arm. But because of friction, the actual output torque is less than the theoretical output torque.

How to Select the best Hydraulic Torque Wrenches

Choosing the proper hydraulic torque wrench depends on many factors. Here are some of these parameters:

Application is an essential thing to think about when choosing the proper hydraulic torque wrench. For example, low-profile wrenches are used in places where access is limited.

A hydraulic wrench meets the bolt specifications, and torque needs to be comprehended. Most clients know what bolts they need, but we need to know what kind of torques they need. It would help if you saw the bolt's material and strength grade to compare it to the table the wrench manufacturer made. To take off lock bolts, use the right amount of torque

Which Kinds of Hydraulic Torque Wrenches Do We Offer?

Orione Hydropower provides a comprehensive selection of hydraulic wrenches to satisfy the needs of industrial applications that demand torque or force accuracy. Our hydraulic wrenches have recently tightened many nuts, whereas their manual counterpart is nearly impossible.

Why Choose Orione Hydropower?

Orione Hydropower has made a name for itself by selling its hydraulic power jack and other products to various businesses, such as steel mills and power plants. We also sell hydraulic tools that are designed for specific uses.

Since it started, Orione Hydropower has built a solid customer base by focusing on application solutions, timely delivery of hydraulic products, and service offering of hydraulic jacks, hydraulic systems, and hydraulic torque wrenches.

And elements almost for all industries, such as Steel Plants, Machine Tools, Cement Industries, Process Industries, Construction, and OEM.

The company's primary goal is to provide high-quality, reliable services to businesses. Our ideas and actions are not centered on the product itself but on its purpose and finding cost-effective ways to meet or exceed our customers' expectations.

Orione Hydropower is the best manufacturer of hydraulic torque wrench suppliers, exporters, and hydraulic torque wrenches in Navi Mumbai, India. We provide this hydraulic torque wrench all over India.