- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

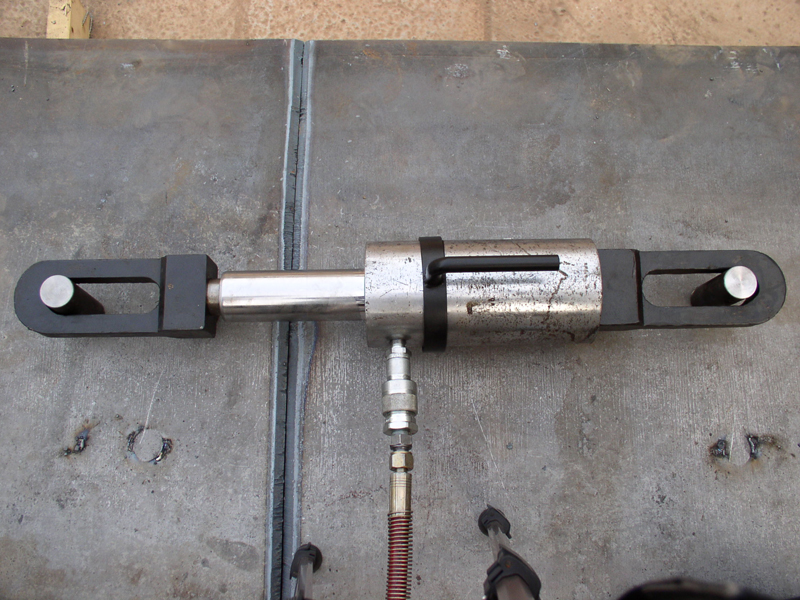

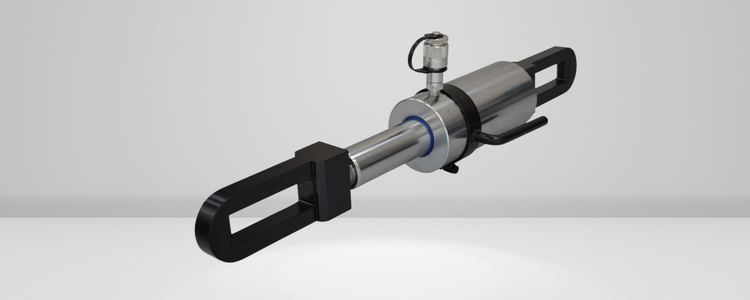

Pull Cylinder - Plain Ram, Single Acting, Spring Return

Hydraulic pull cylinders are devices that use hydraulic pressure to exert a pulling force on a cable or a bar. They are often used for line tensioning, which applies a controlled amount of energy to a rope to make it taut and stable. Cable tensioning is essential for bridges, cranes, elevators, and power lines.

Hydraulic pull cylinders are powerful and versatile devices that can perform various pulling tasks precisely and efficiently. They are made of solid materials such as steel that withstand high pressures and forces. They are also easy to utilize and maintain, as they have few moving parts and require minimal lubrication.

Orione Hydropower is a leading manufacturer and supplier of Hydraulic pull cylinders in Navi Mumbai, Maharashtra, India. Our high-end designs are made of metal to prevent corrosion and withstand wear. As a trusted manufacturer in Navi Mumbai, we use only the finest quality materials to deliver the best options to our customers. Please browse our website and place your order according to your preferences.

Capacity 10 - 30 ton / Stroke 150 mm / Max. Working Pressure 700 bar

Technical :

| Capacity (ton) | Capacity (kN) | Stroke (mm) | Model | Effective area (cm2) | Oil cap. (cc) | Extended (mm) | Closed height (mm) | Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 10 | 107 | 150 | OSPC 10-150 | 15.3 | 230 | 691 | 541 | 14 |

| 20 | 225 | 150 | OSPC 20-150 | 32.1 | 485 | 770 | 620 | 28 |

| 30 | 332 | 150 | OSPC 30-150 | 47.4 | 715 | 820 | 670 | 48 |

What is a Hydraulic Pull Cylinder?

A hydraulic pull cylinder is a type of hydraulic cylinder that is designed to produce a pulling force through a linear stroke. Hydraulic cylinders are mechanical actuators that use pressurized hydraulic fluid, usually oil, to move a piston connected to a piston rod. The piston separates the cylinder into two chambers: the cap end and the rod end. The hydraulic pressure acts on the piston to do linear work and motion.

Hydraulic pull cylinders are ideal for applications that require cable and bar tensioning, such as construction, mining, bridge building, and power transmission. They are also used for pulling heavy loads or objects that cannot be pushed. Hydraulic pull cylinders are typically single-acting, meaning they have one port for fluid inlet and outlet, and spring return, meaning they use a spring to retract the piston rod when the pressure is released.

Features of hydraulic pull cylinders

Advantages of Hydraulic Pull Cylinders

A hydraulic pull cylinder is a device that uses pressurized fluid to exert a pulling force on a load. Hydraulic pull cylinders are commonly used in construction, mining, manufacturing, and automotive repair applications. They have several advantages over other pulling devices, such as mechanical jacks, winches, or hoists. In this blog post, we will discuss some of the main benefits of using a hydraulic pull cylinder for your pulling needs.

1. High Force and Power

One of the most apparent advantages of a hydraulic pull cylinder is its ability to generate a high amount of force and power with a relatively small size and weight. Hydraulic pull cylinders can produce strengths ranging from a few hundred to several thousand pounds, depending on the size and pressure of the cylinder. It means you can use a hydraulic pull cylinder to move heavy loads that would otherwise require more extensive and cumbersome equipment.

2. Precise Control and Adjustment

Another benefit of a hydraulic pull cylinder is its precise control and adjustment of the pulling force and speed. By varying the amount and direction of the fluid flow in the cylinder, you can easily adjust the power and speed of the pulling action. You can also use valves, regulators, or pumps to control the fluid flow remotely or automatically. It allows you to fine-tune the pulling operation to suit your specific needs and preferences.

3. Safety and Reliability

A hydraulic pull cylinder is also a safe and reliable device that can withstand harsh conditions and environments. Hydraulic fluid is non-flammable and non-explosive, unlike some other types of liquids or gases that are used in pneumatic or electric devices. Hydraulic fluid also lubricates the internal components of the cylinder, reducing friction and wear and tear. Also, hydraulic pull cylinders have fewer moving parts than mechanical devices, reducing the risk of malfunction or breakdown.

4. Versatility and Compatibility

Finally, a hydraulic pull cylinder is a versatile and compatible device that can be used for various purposes and applications. Hydraulic pull cylinders come in different sizes, shapes, designs, and configurations to suit other loads and situations. You can also attach accessories or attachments to the cylinder, such as hooks, clamps, chains, or cables, to enhance its functionality and performance. Furthermore, hydraulic pull cylinders can be easily connected to other hydraulic devices or systems, such as pumps, hoses, valves, or gauges, to create a complete hydraulic circuit.

Applications of Hydraulic Pull Cylinders

A pull cylinder is a pneumatic or hydraulic cylinder that uses compressed air or fluid to pull a piston rod in one direction. The piston rod is attached to a load or a mechanism that needs to be moved or actuated. A pull cylinder can be single-acting or double-acting, depending on whether it uses pressure or spring to return the piston rod to its original position.

Pull cylinders have various applications in different industries and machines. Some of the common uses of pull cylinders are:

Actuating remote mechanisms

Pull cylinders can be used to pull on levers, cables, chains, or other devices that control or operate remote instruments. For example, pull cylinders can open and close valves, doors, gates, or hatches far from the operator or the control panel.

Pulling on clamp plates

Pull cylinders can apply clamping force on plates, bars, rods, or other objects that need to be held securely. For example, pull cylinders can clamp workpieces in machining, welding, or assembly processes.

Manual assembly with "C" washers

Pull cylinders can be used with removable "C" washers as a manual assembly, automatically activated pull clamp. The "C" washer is placed around the piston rod and acts as a stopper when the piston rod is retracted. The pull cylinder can then pull the washer and the attached object into position. This method can help assemble components with irregular shapes or sizes.

Lifting or lowering loads

Pull cylinders can be used to lift or lower loads suspended by ropes, chains, cables, or other means. For example, pull cylinders can raise or lower containers, pallets, crates, or other materials in warehouses, factories, or construction sites.

Rotating objects

Pull cylinders can be used to rotate objects mounted on pivots, hinges, bearings or other devices that allow rotation. For example, pull cylinders can turn wings, flaps, propellers, or turbines in aerospace applications.

Pull cylinders are versatile and powerful devices that can provide linear motion and force for various applications. They can be customized to suit different specifications and requirements, such as bore size, stroke length, mounting style, port size, seal type, and cushioning. They can also be combined with other pneumatic or hydraulic components, such as valves, regulators, filters, hoses, fittings, and sensors, to create complex and efficient systems.

How to Use Hydraulic Pull Cylinders for Cable Tensioning?

The basic principle of hydraulic pull cylinders is that they have a plunger that extends and retracts by the action of hydraulic fluid. The plunger is attached to a cable or a bar by a hook, a lug, or a custom attachment. When hydraulic fluid is pumped into the cylinder, the plunger extends and pulls the cable or bar. When the liquid is released, the plunger retracts and releases the line or the bar.

Hydraulic pull cylinders are valuable tools for cable tensioning and other pulling applications. By following some essential steps and precautions, you can use them effectively and safely for your projects.

Steps to use

To use hydraulic pull cylinders for cable tensioning, you need to follow these steps:

1. Select the appropriate hydraulic pull cylinder for your application. It would help if you considered factors such as the pulling capacity, the stroke length, the mounting type, and the attachments. You can find different hydraulic pull cylinders from various manufacturers, such as Enerpac, Simson Power Tools, and Hy Power Clamps.

2. Mount the hydraulic pull cylinder on a fixed support, such as a beam, a wall, or a frame. Ensure the cylinder is aligned with the direction of the cable or the bar you want to tension.

3. Attach the plunger end of the cylinder to the cable or the bar using a hook, a lug, or a custom attachment. Make sure the extension is secure and can withstand the pulling force.

4. Connect the hydraulic pull cylinder to a hydraulic pump or an intensifier using hoses and fittings. Make sure there are no leaks or kinks in the hoses.

5. Pump hydraulic fluid into the cylinder until you reach the desired cable or bar tension. You can measure the stress using a load cell, a dynamometer, or a strain gauge. You can also use a pressure gauge to monitor the hydraulic pressure in the cylinder.

6. Lock or clamp the cable or the bar in place using anchors, bolts, nuts, or other devices. Ensure there is no slack or sagging in the thread or the bar.

7. Release the hydraulic fluid from the cylinder and detach it from the cable or the bar.

Why Choose Orione Hydropower?

As you can see, a hydraulic pull cylinder is an advantageous device that can help you with your pulling needs. It offers high force and power, precise control and adjustment, safety and reliability, and versatility and compatibility.

If you are looking for a quality hydraulic pull cylinder for your project or business, you can browse our selection on our website. We offer a wide range of hydraulic pull cylinders with different specifications and features to meet your requirements. Contact us today for more information or to place an order.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfill or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and trader of hydraulic pull cylinders in Navi Mumbai, India. These hydraulic pull cylinders are available across India. Please quote here if you have this product!