- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

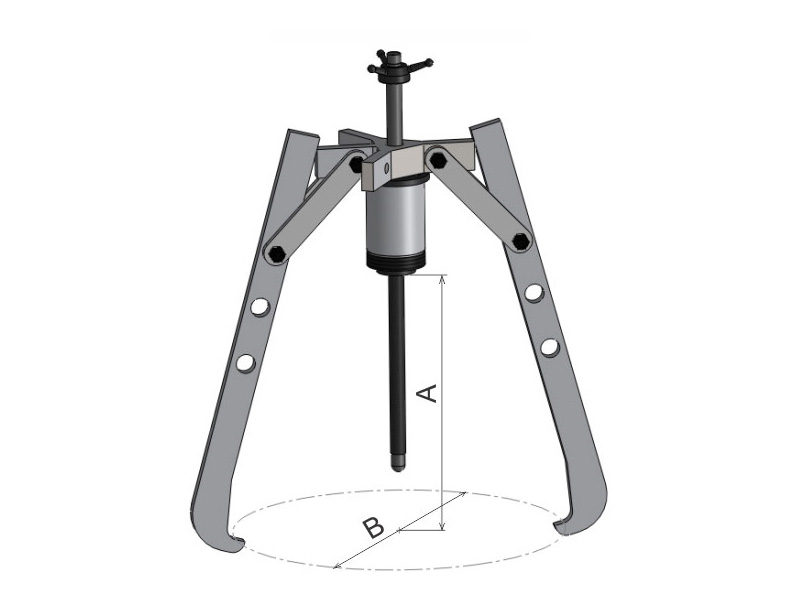

Hydraulic Jaw Pullers Suppliers

Consider a Hydraulic jaw puller if you are looking for a tool to help remove bearings, gears, pulleys, or other components from shafts. A Hydraulic jaw puller is a mechanical device consisting of a beam, a spindle, and two or more arms with claws that grip the object to be pulled. By turning the spindle, you can apply force to the thing and pull it off the shaft.

Hydraulic Jaw pullers are essential for many mechanical applications, such as automotive, industrial, agricultural, or marine. They can save time, money, and effort by making removing press-fitted parts more accessible and faster. However, Hydraulic jaw pullers should be used with care and caution, following the manufacturer's instructions and safety guidelines. Improper use of jaw pullers can damage the part of the shaft or injury the user.

Capacity 10 - 100 ton

Technical :

| Model | No. of Jaws |

Capacity (ton) |

Capacity (kN) |

Cylinder Model |

Stroke (mm) |

Reach A (mm) |

Spread B (mm) |

|---|---|---|---|---|---|---|---|

| OPA 10 2JP | 2 | 10 | 110 | OSH 10-100 | 100 | 295 | 395 |

| OPA 10 3JP | 3 | 10 | 110 | OSH 10-100 | 100 | 295 | 395 |

| OPA 20 2JP | 2 | 20 | 231 | OSH 20-100 | 100 | 260 | 425 |

| OPA 20 3JP | 3 | 20 | 231 | OSH 20-100 | 100 | 260 | 425 |

| OPA 30 2JP | 2 | 30 | 298 | OSH 30-100 | 100 | 380 | 610 |

| OPA 30 3JP | 3 | 30 | 298 | OSH 30-100 | 100 | 380 | 610 |

| OPA 50 2JP | 2 | 50 | 550 | OSH 50-100 | 100 | 750 | 855 |

| OPA 50 3JP | 3 | 50 | 550 | OSH 50-100 | 100 | 750 | 855 |

| OPA100 2JP | 2 | 100 | 1093 | ODH 100-100 | 100 | 1040 | 1230 |

| OPA100 3JP | 3 | 100 | 1093 | ODH 100-100 | 100 | 1040 | 1230 |

Retract pressure is preset at 1,300 PSI.

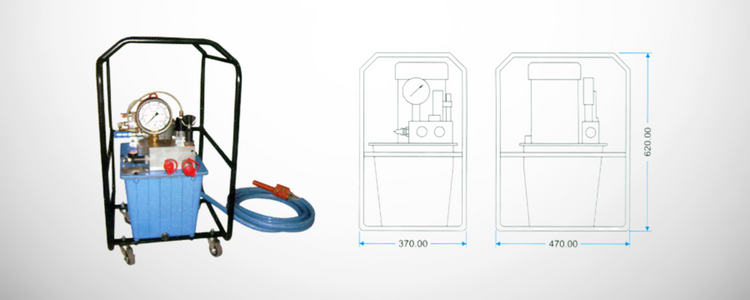

EP 1000 - High Flow - High Speed For Heavy Duty Application

| Resvr.Size (Gal.) | Valve | Motor Specifications |

Flow Rate @ 115 VAC | Weight | |||

| Control | Type | 600 psi | 10,000 psi | Kg | Lbs | ||

| 2 | Solenoid | 3 Way/2 Pos. | 1.5 HP Rotary Air | 9.83 Lpm | 0.82 Lpm | 27 | 59 |

What is a hydraulic jaw puller?

A hydraulic jaw puller is a tool that uses hydraulic pressure to apply a controlled force on the component you want to remove. It consists of a hydraulic cylinder, a pump, a hose, and jaws that can be attached to the element. The jaws can be two or three, depending on the shape and size of the component.

The hydraulic jaw puller works by pulling the component away from the shaft or bore while preventing it from tilting or slipping. The hydraulic cylinder provides a smooth and steady force that the pump can adjust. The jaws grip the component securely and evenly, minimizing the risk of damage.

Features of Hydraulic Jaw pullers

Many features of a jaw puller make it a valuable tool for various applications. Here are some of them in list format:

Adjustable jaws

The jaws of a jaw puller can be adjusted to fit different sizes and shapes of parts. Some jaw pullers have reversible jaws that can be switched between internal and external pulling. It means you can use the same tool to pull apart from inside or outside a hole.

Self-centering

The central bolt of a jaw puller is designed to align itself with the center of the part and the shaft. It ensures that the pulling force is applied evenly and prevents damage to the components or the shaft.

Self-locking

The jaws of a jaw puller are self-locking, meaning they tighten their grip on the part as the pulling force increases. It prevents the component from slipping or falling off during the operation.

Safety release

Some jaw pullers have a safety release mechanism that allows you to release the tension on the bolt and the jaws quickly and safely. It helps you avoid injuries or accidents when removing the tool from the part.

Versatility

A jaw puller can remove various types of parts, such as bearings, gears, pulleys, sprockets, flywheels, and more. It can also be used with different types of shafts, such as tapered, splined, keyed, or threaded.

Applications of Hydraulic Jaw pullers

Hydraulic Jaw pullers are mechanical tools that dismount bearings and other components from shafts or axles. They consist of a beam, a spindle, and two or three arms with hooks or jaws that can grip the inner or outer surface of the component. Hydraulic Jaw pullers can be used for various applications in different industries, such as automotive, industrial, maintenance, and repair.

Here are some examples of how Hydraulic Jaw Pullers can be used:

Tie rod tool

Removing old tie rods is usually tricky, especially when the vehicle is old and rusty. A jaw puller can help to loosen and remove the tie rod end from the steering knuckle without damaging the threads or the rubber boot. A two-jaw puller with a narrow grip width and a short arm's length is suitable for this application.

Three jaw pullers

One of the most versatile pullers, the three-jaw puller, has three articulating arms with both external and internal hooks. It can be used to pull bearings, gears, pulleys, wheels, and other components from shafts or axles. The three-jaw puller can also extract recessed parts with no tapped holes. A three-jaw puller with a wide grip width and a long arm's length can handle larger and heavier elements.

Balancer tool

Some older model Chevy and Chrysler engines have special crankshaft dampers/pulleys that require removal for many jobs. A jaw puller can help to remove the balancer without damaging the crankshaft or the pulley. A three-jaw puller with a cone system for automatic centering and secure positioning of arms is ideal for this application.

Steering wheel

Removing a steering wheel can be challenging, especially if it is stuck on the steering column. A jaw puller can help to apply even pressure on the steering wheel hub and pull it off the column without damaging the horn or the airbag. A two-jaw puller with a wide grip width and a long arm's length suits this application.

Pulley

Removing a pulley from a shaft or an axle can be tricky, especially if it is tight or corroded. A jaw puller can help to grip the pulley from behind and pull it off without damaging the shaft or the belt. A two-jaw or a three-jaw puller with a narrow grip width and a short arm's length is suitable for this application.

Types of Hydraulic Jaw Pullers

Different types of Hydraulic jaw pullers are available in the market, depending on the object's size, shape, and application to be removed. Some of the most common types are:

Reversible jaw pullers

These pullers have arms that can be reversed to allow for internal or external pulling. They are suitable for various bearing and component sizes and can be used with or without extension pieces. Reversible jaw pullers are versatile and robust tools that handle most pulling jobs.

Hydraulic jaw pullers

These pullers have a hydraulic cylinder and pump integrated into the spindle, which makes them easy to use and assembly-free. They also have a safety valve that prevents overloading and damage to the spindle and puller. Hydraulic jaw pullers are ideal for quick and effortless bearing dismounting and can generate high pulling forces with minimal torque.

Tri-section pulling plates

These are accessories that can be used with jaw pullers to facilitate the removal of bearings mounted on tapered or cylindrical seats. They consist of three sections that fit behind the bearing and distribute the pulling force evenly over the entire bearing circumference. Tri-section pulling plates can prevent damage to the bearing and shaft during dismounting.

Jaw pullers are essential for any mechanic or DIY enthusiast who needs to remove bearings or other components from shafts. They are easy-to-use, safe, and practical tools that save time and effort in many projects.

Advantages of Hydraulic Jaw Pullers

A Hydraulic jaw puller is a tool to remove gears, pulleys, bearings, and other press-fitted parts from a shaft or spindle. It consists of a central screw that pushes against the end of the shaft and two or more jaws that grip the part to be removed. By turning the screw, the jaws apply a pulling force on the part until it comes off.

Hydraulic Jaw pullers have several advantages over other methods of removing press-fitted parts, such as hammers, pry bars, or heat. Some of these advantages are:

Safety Precautions

However, before using a Hydraulic jaw puller, it is essential to follow some safety precautions, such as:

How to Use a Hydraulic Jaw Puller for Removing Bearings and Gears

If you work with machinery, you may have encountered situations where you need to remove bearings, gears, pulleys, or other press-fit assemblies from a shaft or a bore. These components can be difficult to dislodge without damaging them or the surrounding parts. That's why you need a hydraulic jaw puller.

To use a hydraulic jaw puller, you need to follow these steps:

1. Select the appropriate jaw puller for your application. You need to consider the puller's capacity, reach, and spread. The power is the maximum force that the puller can exert, measured in tons or kilonewtons. The reach is the distance from the tip of the cylinder to the center of the jaws, measured in millimeters. The spread is the maximum distance between the jaws, measured in millimeters. You can find these specifications on the product manual or website.

2. Attach the hose to the cylinder and the pump. Make sure there are no leaks or kinks in the hose. Fill the pump reservoir with hydraulic oil if needed.

3. Position the cylinder behind the component you want to remove. Ensure there is enough space for the cylinder to move back as it pulls the element.

4. Attach the jaws to the component. Depending on the type of jaws, you may need to screw them onto the cylinder or slide them onto a threaded rod. Please ensure the jaws are aligned with the center of the component and grip it firmly.

5. Pump the handle of the pump to generate hydraulic pressure. You will see the cylinder extend and pull the component away from the shaft or bore. Keep pumping until the element is completely removed or until you reach the maximum stroke of the cylinder.

6. Release the pressure by turning a knob or a valve on the pump. You will see the cylinder retract and release the component.

7. Detach the jaws from the component and the cylinder. Disconnect the hose from the cylinder and the pump. Store the puller in a clean and dry place.

Why Choose Orione Hydropower?

A hydraulic jaw puller is a valuable tool for removing bearings, gears, pulleys, and other press-fit assemblies without damaging them or their surroundings. It is easy to use and can save you time and money in maintenance and repair work.

If you want a high-quality hydraulic jaw puller, you can check out Orione Hydropower's products. We offer hydraulic jaw pullers with two or three jaws, capacities ranging from 10 to 100 tons, and adjustable reach and spread. They also provide hydraulic power packs, hand pumps, hydraulic cylinders, and other hydraulic equipment for various applications.

Orione Hydropower is a leading manufacturer, exporter, wholesaler, and trader of hydraulic equipment based in Jharkhand, India. We have more than 18 years of experience providing reliable and innovative solutions for the construction, infrastructure, industrial, automotive, and marine sectors.