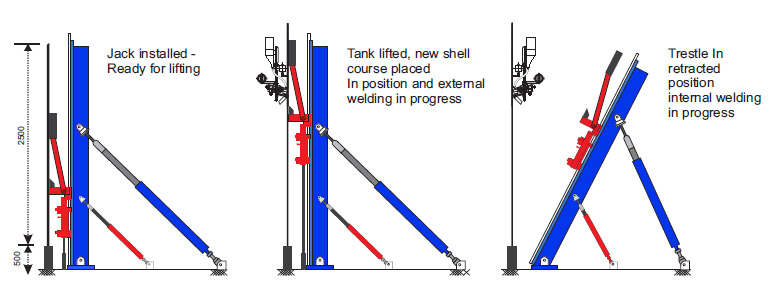

- Hydraulic Tank Jack

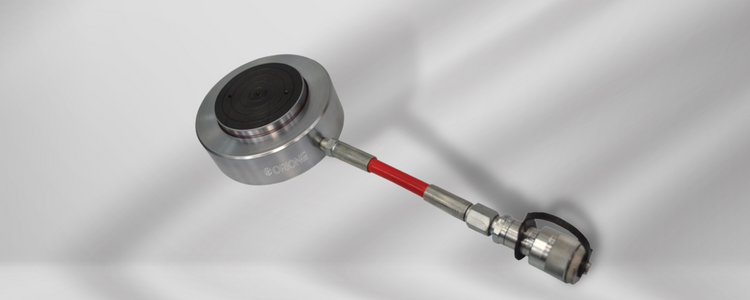

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Traction Motor Pinion Dismounting and Mounting Equipment Suppliers

If you work with traction motors, you know how crucial it is to keep the right tools for dismounting and mounting pinions. Pinions are the gears that connect the traction motor shaft to the locomotive's axle or train. They are subject to high torque and wear and must be replaced occasionally to ensure optimal performance and safety.

However, replacing pinions is a challenging task. It requires specialized equipment that can handle the pinions' heavy weight and tight fit and the high temperatures and pressures involved. With the proper equipment, you can avoid damaging the pinions, the motor shaft, or the axle, leading to costly repairs or accidents.

That's why you need traction motor pinion dismounting and mounting equipment from TMPE. TMPE is a leading manufacturer and supplier of high-quality tools and machines for traction motor maintenance. We have over 20 years of experience designing and producing equipment that meets the highest reliability, durability, and efficiency standards.

Our traction motor pinion dismounting and mounting equipment consists of two main components: a hydraulic press and a heating device. The hydraulic press is used to apply controlled force to the pinion, either to remove it from the shaft or to install it on the axle. The heating device is used to heat the pinion before mounting, which expands its diameter and makes it easier to slide onto the axle.

Features of Traction Motor Pinion Dismounting and Mounting Equipments

Traction Motor Pinion Dismounting and Mounting Equipment is a specialized tool for railway maintenance. It is used to remove and install the pinion gears on the traction motors of electric locomotives and high-speed trains. The equipment has several features that make it efficient, safe, and easy to use.

The hydraulic press and the heating device are designed to work together seamlessly, with features such as:

With our traction motor pinion dismounting and mounting equipment, you can save time, money, and effort in your traction motor maintenance. You can reduce downtime, improve efficiency, and enhance safety. You can also extend the lifespan of your pinions, motors, and axles, which reduces waste and environmental impact.

Applications of Traction Motor Pinion Dismounting and Mounting Equipment

Traction motor pinion is a vital component of electric locomotives that transfers the torque from the motor to the axle. It is subject to high stress and wear due to the heavy load and frequent acceleration and deceleration of the locomotive. Therefore, regular inspection and maintenance are required to ensure optimal performance and safety.

However, dismounting and mounting the traction motor pinion takes work. It involves lifting the locomotive, removing the wheelset, separating the motor from the axle, applying hydraulic pressure to pull out or push in the pinion, and reassembling the components. This process can take several hours and requires specialized tools and skilled workers.

To overcome these challenges, some railway companies have adopted traction motor pinion dismounting and mounting equipment (TMPDME) that can simplify and speed up the process. TMPDME is a portable device that can be attached to the wheelset without lifting the locomotive. It uses a hydraulic cylinder to apply controlled force to dismount or mount the pinion with minimal damage. It also has a digital display that shows the pressure and displacement data for monitoring and recording purposes.

Some of the applications and benefits of TMPDME are:

Reduced downtime and cost

TMPDME can reduce the time required for dismounting and mounting the pinion from hours to minutes, saving labor costs and increasing operational efficiency. It can also lower the chance of damage to the pinion, motor, axle, and wheelset, which can lower the maintenance cost and extend the service life of the components.

Improved safety and quality

TMPDME can eliminate the need for lifting the locomotive, reducing the risk of accidents and injuries. It can also provide precise and consistent force to dismount or mount the pinion, improving the operation's quality and reliability. Moreover, it can record the pressure and displacement data for quality control and traceability.

Enhanced flexibility and convenience

TMPDME is a compact and lightweight device that one or two workers can easily transport and operate. It can be used for different traction motors and pinions with various diameters and lengths. Depending on availability, it can also be powered by a battery or an external power source.

Working process of Traction Motor Pinion Dismounting and Mounting Equipment

Traction Motor Pinion Dismounting and Mounting Equipment is a unique instrument that can be utilized to remove and install the pinion gear on the traction motor of a locomotive. The pinion gear is the part that connects the traction motor to the axle and transfers the torque to the wheels. The pinion gear must be replaced periodically due to wear and tear or damage.

The working process of Traction Motor Pinion Dismounting and Mounting Equipment can be summarized in the following steps:

1. The equipment consists of a hydraulic pump, a hydraulic cylinder, a puller head, a pusher head, and a set of adapters for different sizes of pinion gears. The equipment is mounted on a wheeled cart for easy transportation and operation.

2. The equipment is connected to the traction motor by removing the inspection cover on the motor housing and inserting the puller or pusher head into the hole. The puller head is used to dismount the pinion gear from the motor shaft, while the pusher head is used to mount the new pinion gear onto the shaft.

3. The hydraulic pump is activated to generate hydraulic pressure, which drives the hydraulic cylinder to move the puller head or the pusher head along the motor shaft. The puller or pusher head has a set of jaws that grip the pinion gear and apply a pulling or pushing force to it.

4. The pinion gear is gradually dismounted or mounted by repeating the hydraulic pumping and releasing process until the pinion gear is wholly separated from or attached to the motor shaft. The pinion gear can be removed or installed by hand or with a crane.

5. The equipment is disconnected from the traction motor by reversing the steps above and replacing the inspection cover on the motor housing. The equipment is then moved to another traction motor for repeated operation.

Traction Motor Pinion Dismounting and Mounting Equipment is a valuable tool that can save time and labor in maintaining and repairing locomotive traction motors. It can also improve the safety and reliability of locomotive operation by ensuring proper alignment and fitment of pinion gears.

Why Choose Orione Hydropower?

TMPDME is a valuable device that facilitates dismounting and mounting traction motor pinion in electric locomotives. It can offer various advantages, such as reduced downtime and cost, improved safety and quality, and enhanced flexibility and convenience. It can be a valuable tool for railway companies that want to improve their maintenance efficiency and effectiveness.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfill or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and trader of hydraulic products for railways in Chhattisgarh, India. These hydraulic products for railways are available across India. Please quote here if you have this product!