- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

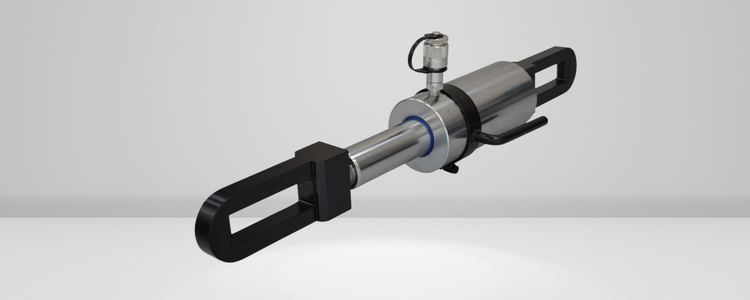

Double Acting Cylinders Suppliers

A double acting cylinder is a type of hydraulic cylinder that can produce force and motion in both directions by applying pressure on both ends of the piston. Unlike single acting cylinders, which rely on external forces or springs to return the piston to its original position, double acting cylinders can control the speed and direction of the piston rod using valves and pumps.

Double acting cylinders are widely used in industrial applications, such as presses, lifts, cranes, excavators, and other machines that require precise and powerful movements. They are also more efficient and versatile than single acting cylinders, as they can perform more work with less fluid and space.

Double acting cylinders are widely available in different sizes, shapes, configurations, and specifications to suit different needs and requirements. They offer many advantages, such as high power density, reliability, efficiency, flexibility, and safety. They are also easy to install, maintain, and operate with proper valves, controllers, sensors, and accessories.

Orione Hydropower is a leading manufacturer and supplier of Double Acting Cylinders in Haryana, India. Our high-end designs are made of metal to prevent corrosion and withstand wear. As a trusted manufacturer in Haryana, we use only the finest quality materials to deliver the best options to our customers. Please browse our website and place your order according to your preferences.

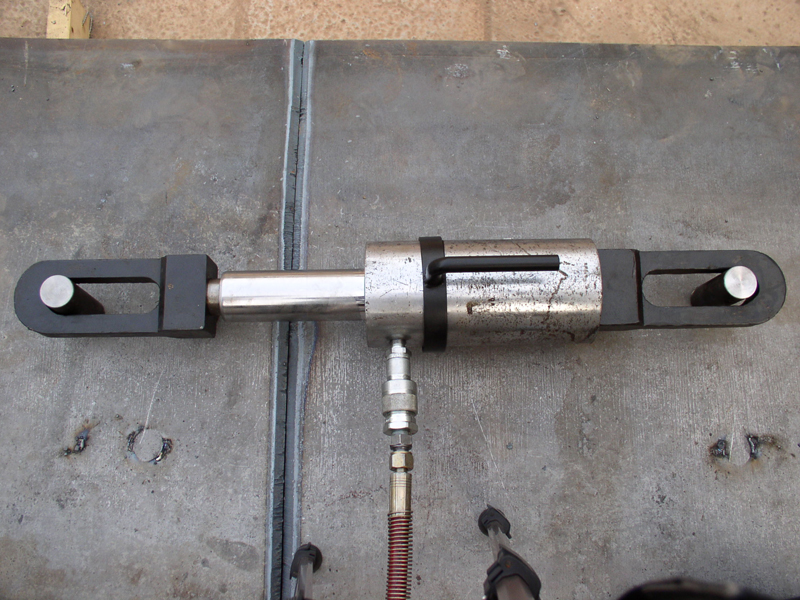

Capacity 10 - 30 ton / Stroke 150 mm / Max. Working Pressure 700 bar

Technical :

| Capacity (ton) | Capacity (kN) | Stroke (mm) | Model | Effective area (cm2) | Oil cap. (cc) | Extended (mm) | Closed height (mm) | Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 10 | 107 | 150 | OSPC 10-150 | 15.3 | 230 | 691 | 541 | 14 |

| 20 | 225 | 150 | OSPC 20-150 | 32.1 | 485 | 770 | 620 | 28 |

| 30 | 332 | 150 | OSPC 30-150 | 47.4 | 715 | 820 | 670 | 48 |

Features of Double Acting cylinders

Applications of Double Acting Cylinders

A double acting cylinder is a pneumatic or hydraulic cylinder that can produce force and motion in both directions by alternating the flow of pressurized fluid to either side of the piston. Unlike a single acting cylinder, which can only extend or retract under power, a double acting cylinder can control the speed and position of the piston rod in both directions. It makes it more versatile and suitable for various applications that require precise and reversible movement.

Some of the standard applications of double acting cylinders are:

Opening and closing an entrance, carwash, or loading dock doors

A double acting cylinder can be mounted horizontally or vertically to operate a gate or door that needs to be opened and closed frequently and securely. The cylinder can be controlled by a valve that switches the fluid flow to extend or retract the piston rod as needed.

Opening and closing valves

A double-acting cylinder can actuate a valve that regulates fluid or gas flow in a pipeline or tank. The cylinder can be attached to the valve stem or handle and moved to open or close the valve according to the signal from a controller or a sensor.

Moving items onto or off conveyors

A double acting cylinder can be used to transfer items from one conveyor belt to another or to load or unload items from a conveyor system. The cylinder can be equipped with a gripper, a suction cup, a magnet, or any other device that can hold and release the items. The cylinder can be synchronized with the speed and direction of the conveyor belts to ensure smooth and accurate movement.

Moving the conveyor systems themselves

A double acting cylinder can also be used to adjust the position or angle of a conveyor system, for example, to align it with another conveyor or a machine. The cylinder can be mounted on a base or a frame that supports the conveyor and moves horizontally or vertically as required.

Silk screening

A double acting cylinder can be used to operate a silk screen machine that prints images or texts on fabrics or other materials. The cylinder can be attached to a squeegee-like device that sweeps ink over the fabric in one direction, then reverses itself to clean in the opposite direction. It ensures even coverage and quality of the print.

Knifing

A double acting cylinder can be used to cut materials such as paper, cardboard, plastic, or metal into smaller pieces or shapes. The cylinder can be connected to a knife or a blade that moves at the same speed as the material to cut it on the fly, then retracts and repositions for the next cut.

Paint or Powder Coat Spraying

A double acting cylinder can be used to spray paint or powder coat on surfaces such as metal, wood, or plastic. The cylinder can be linked to a sprayer that moves back and forth or up and down to cover the surface evenly and uniformly.

Presses and punches

A double acting cylinder can be used to apply force and pressure on materials such as metal, wood, plastic, or rubber to shape them, bend them, stamp them, or punch holes in them. The cylinder can be mounted on a press or a punch machine that delivers high force and speed to perform the desired operation.

Advantages of Double Acting Cylinders

A double acting cylinder is a pneumatic or hydraulic cylinder that can apply force in both directions using pressurized fluid on either side of the piston. It allows for more control and versatility in the movement of the cylinder and higher efficiency and power.

One of the main advantages of a double acting cylinder is that it can produce more force than a single acting cylinder of the same size and pressure. It is because a single acting cylinder only uses one side of the piston to generate power, while a double acting cylinder uses both sides. For example, if a single acting cylinder has a piston area of 10 cm2 and a pressure of 100 bar, it can produce a force of 1000 N. However, if a double acting cylinder has the same piston area and stress, it can create a force of 2000 N by using 100 bars on both sides of the piston.

Another advantage of a double acting cylinder is that it can perform more complex and precise movements than a single acting cylinder. A single acting cylinder can only move in one direction, either extending or retracting, depending on the port's location. A double acting cylinder can move in both directions by alternating the fluid flow to either side of the piston. It allows for more flexibility and accuracy in positioning and speed control. For example, a double acting cylinder can be used to lift and lower a load with variable speed and force by adjusting the pressure and flow rate of the fluid.

A third advantage of a double acting cylinder is that it can be more energy efficient and environmentally friendly than a single acting cylinder. A single acting cylinder requires a spring or a weight to return the piston to its original position after each stroke, which consumes energy and creates noise. A double acting cylinder does not need any external force to return the piston, as it uses the fluid pressure on the opposite side. It reduces energy consumption, noise pollution, and wear and tear on the cylinder components.

How does a Double Acting cylinder work?

A double acting cylinder consists of a cylindrical barrel, a piston, a piston rod, and two ports. The piston divides the barrel into the blank-end chamber and the rod-end chamber. The piston rod extends from one end of the cylinder and connects to an external mechanism, such as a crankshaft or a lever. The two ports allow fluid to enter and exit the cylinder and are controlled by a valve.

To extend the cylinder, fluid is pumped into the blank-end chamber through one port, while the liquid is drained from the rod-end chamber through the other port. It creates a pressure difference that pushes the piston and rod to move in one direction. To retract the cylinder, fluid is pumped into the rod-end chamber, while the liquid is drained from the blank-end chamber. It creates a pressure difference that pulls the piston and the piston rod to move in the opposite direction.

The force exerted by a double-acting cylinder depends on the pressure of the fluid, the piston's area, and the piston rod's diameter. The power is more significant in the extension stroke than in the retraction stroke because the scope of the piston rod reduces the adequate size of the piston.

How to select the best Double Acting Cylinder for your application?

A double acting cylinder is a pneumatic or hydraulic cylinder that can extend and retract using pressurized fluid on both piston sides. It allows for more precise and robust motion control than a single acting cylinder, which can only extend using fluid pressure and relies on a spring or gravity to retract.

However, not all double acting cylinders are created equal. There are numerous characteristics to consider when choosing the best one for your application, such as:

The bore size: This is the diameter of the cylinder tube and determines how much force the cylinder can produce. The larger the bore size, the more energy the cylinder can generate, but the more fluid it will consume. You should choose a bore size that matches your required force output and fluid availability.

The stroke length is the distance: The piston can travel inside the cylinder tube. The longer the stroke length, the more movement the cylinder can provide and the more space it will occupy. It would help if you chose a stroke length that fits your available space and desired range of motion.

The rod size: This is the diameter of the piston rod that extends from the cylinder tube. The larger the rod size, the more resistant it will be to bending and buckling under load and the more weight it will add to the cylinder. You should choose a rod size that can withstand your expected load and minimize your weight.

The mounting style: This is how the cylinder is attached to your machine or structure. Many mounting types are available, such as flange, clevis, trunnion, foot, pivot, etc. Each has advantages and disadvantages regarding stability, alignment, flexibility, and ease of installation. It would help to choose a mounting style that suits your application and design.

The seal type: This is what prevents fluid leakage from the cylinder tube and rod. Various types of seals are available, such as O-rings, U-cups, lip seals, etc. Each has its characteristics regarding durability, friction, temperature resistance, and compatibility with different fluids. It would help if you chose a seal type that matches your operating conditions and fluid style.

These are some of the main factors to consider when selecting a double acting cylinder for your application. Of course, you may have other specific requirements or preferences depending on your situation. In any case, you should always consult with a reputable manufacturer or supplier before making a final decision. They can help you find the best double acting cylinder for your needs and budget.

Why Choose Orione Hydropower?

A double acting cylinder is a pneumatic or hydraulic cylinder with many advantages over a single acting cylinder. It can produce more force, perform more complex movements, and be more energy efficient and environmentally friendly. A double acting cylinder can be used in various applications that require high power, precision, and versatility.

If you are searching for an efficient and trustworthy solution for your hydropower needs, consider Orione Hydropower's double acting cylinders. We have a wide range of double acting cylinders that can meet your specific needs and requirements.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfill or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and trader of double acting cylinders in Haryana, India. These double acting cylinders are available across India. Please quote here if you have this product!