- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

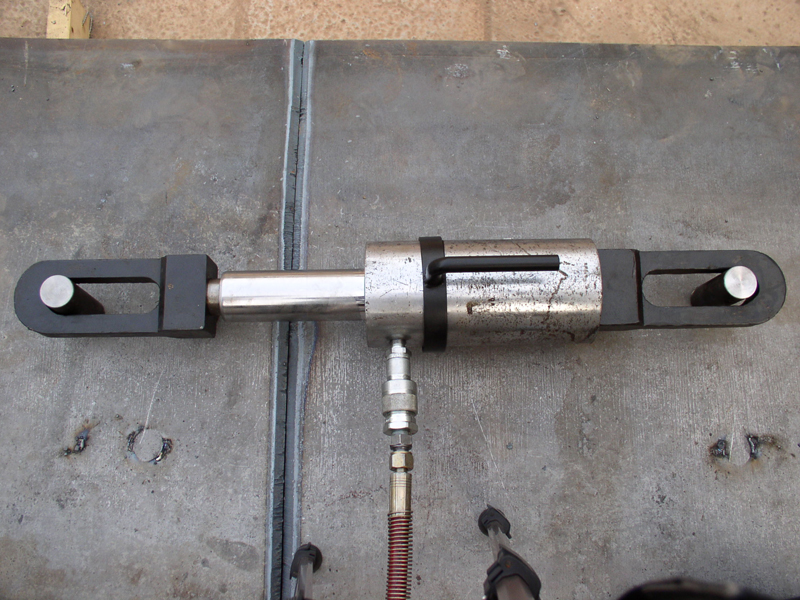

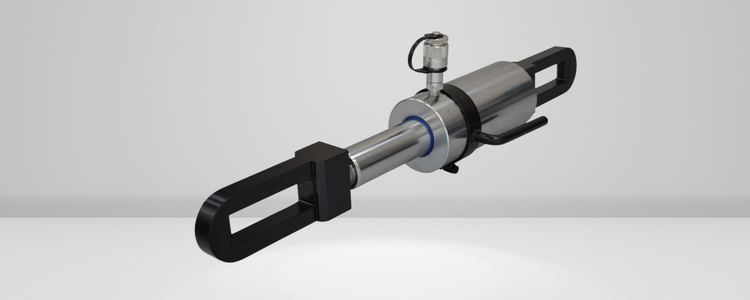

Double Acting Telescopic Cylinders Suppliers

A double acting telescopic cylinder is a hydraulic cylinder with numerous stages or rams that can extend and retract independently. Unlike a single acting telescopic cylinder, which can only extend by hydraulic pressure and retract by gravity or external force, a double acting telescopic cylinder can extend and retract by hydraulic pressure in both directions. It allows for more precise control and greater flexibility in applications where space is limited or variable load direction is required.

A double acting telescopic cylinder has a hollow base member that supports the other stages and is connected to a pivot mount. The base member has a removable end closure that allows access to the internal components of the cylinder.

The other stages are nested inside the base member and have different diameters, with the minor stage being called the plunger or piston rod. Each stage has a piston face on both ends that seals against the inner wall of the next stage. The piston faces also have fluid ports that allow hydraulic fluid to flow between the stages

A double-acting telescopic cylinder's operation depends on the direction and amount of hydraulic fluid supplied to the cylinder. When fluid is supplied to the extended port of the base member, it pushes the first-stage piston to the right, extending it until it reaches its full stroke. Then, the fluid flows through the fluid port of the first-stage piston to the second-stage annulus, pushing the second-stage piston to the right until all stages are fully extended.

When fluid is supplied to the retract port of the base member, it pushes the first-stage piston to the left, retracting it until it uncovers the fluid port of the second-stage piston. Then, the fluid flows through the fluid port of the second stage piston to the first stage annulus, pulling the second stage piston to the left, and so on, until all stages are fully retracted.

Capacity 10 - 30 ton / Stroke 150 mm / Max. Working Pressure 700 bar

Technical :

| Capacity (ton) | Capacity (kN) | Stroke (mm) | Model | Effective area (cm2) | Oil cap. (cc) | Extended (mm) | Closed height (mm) | Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 10 | 107 | 150 | OSPC 10-150 | 15.3 | 230 | 691 | 541 | 14 |

| 20 | 225 | 150 | OSPC 20-150 | 32.1 | 485 | 770 | 620 | 28 |

| 30 | 332 | 150 | OSPC 30-150 | 47.4 | 715 | 820 | 670 | 48 |

Features of Double acting Telescopic cylinders

Some of the features of a double-acting telescopic cylinder in list format are:

Applications of Double acting Telescopic cylinders

A double acting telescopic cylinder is a type of hydraulic cylinder that consists of two or more nested cylinders of different diameters. The cylinders extend and retract in a telescoping manner, allowing for a longer stroke length than a single stage cylinder of the same overall length. Double acting telescopic cylinders can be used for various applications that require high force and long strokes in a compact space. Some of these applications are:

Dump trucks

Double acting telescopic cylinders are commonly used to lift and lower the bed of dump trucks. They provide enough force to handle heavy loads and enough stroke to tilt the bed at a high angle for dumping. They also allow for a low profile when retracted, reducing the overall height of the truck.

Aerial platforms

Double acting telescopic cylinders are also used to raise and lower aerial platforms, such as boom and scissor lifts. They enable the platforms to reach high elevations and adjust their height according to the work environment. They also offer stability and safety for the operators.

Cranes

Double acting telescopic cylinders are often used to extend and retract the boom of cranes. They allow for an extensive range of motion and precise control of the boom position. They also help to balance the load and reduce the stress on the crane structure.

Forklifts

Double acting telescopic cylinders are sometimes used to lift and lower the forks of forklifts. They provide enough force to handle heavy pallets and enough stroke to stack them at different heights. They also improve the visibility and maneuverability of the forklift.

Agricultural equipment

Double acting telescopic cylinders are widely used in various agricultural equipment, such as harvesters, balers, sprayers, loaders, etc. They enable the equipment to perform different functions and to adapt to different terrains. They also enhance the efficiency and productivity of farming operations.

Advantages of Double acting Telescopic cylinders

Double acting telescopic cylinders are widely used in various industries and applications, such as cranes, dump trucks, forklifts, aerial platforms, mining equipment, etc. They offer several advantages over single acting telescopic cylinders, such as:

Higher force output: Since both sides of each piston face are pressurized, a double acting telescopic cylinder can produce more force than a single acting one with the same diameter and stroke.

Better stability: Since each stage can be controlled independently, a double-acting telescopic cylinder can adjust its length and position according to the load and terrain conditions, reducing the risk of tipping or buckling.

Longer service life: Since each stage can be retracted fully into the base member when not in use, a double acting telescopic cylinder can reduce wear and tear on its seals and surfaces, extending its service life.

Disadvantages of Double Acting Telescopic Cylinders

However, double acting telescopic cylinders also have some drawbacks compared to single-acting ones, such as:

Higher cost: A double-acting telescopic cylinder requires more components and machining than a single-acting one; it is more expensive to manufacture and maintain.

Higher weight: Since a double acting telescopic cylinder has more material and fluid than a single-acting one, it is heavier and may affect the performance and fuel efficiency of the vehicle or machine it is mounted on.

Higher complexity: Since a double acting telescopic cylinder involves more sealing and fluid routing than a single acting one, it is more prone to leakage and malfunction if not designed and installed correctly.

How To Select The Best Double Acting Telescopic Cylinder?

A double acting telescopic cylinder is a type of hydraulic cylinder that can extend and retract using hydraulic pressure in both directions. It consists of a series of nested cylinders of different diameters that slide inside each other. The advantage of this design is that it can provide a long stroke length with a compact retracted length.

However, choosing the best double acting telescopic cylinder for your application can be challenging, as there are many factors to consider. Here are some suggestions to help you make the best decision.

1. Determine the required stroke length and retracted length. The stroke length is the distance the cylinder can extend, while the retracted length is the distance that the cylinder occupies when entirely collapsed. You need to ensure that the cylinder can fit in your available space and provide enough extension for your operation. The ratio between the stroke length and the retracted length is called the extension ratio, and it depends on the number and size of the stages in the cylinder—generally, the more stages, the higher the extension ratio and the higher the cost and complexity.

2. Determine the required load capacity and operating pressure. The load capacity is the maximum force that the cylinder can exert or withstand, while the operating pressure is the hydraulic pressure applied to the cylinder. It would help if you ensured the cylinder could handle your load and pressure requirements without exceeding its limits or causing damage. The load capacity and operating pressure depending on the bore size and wall thickness of each stage in the cylinder. Generally, the larger the bore size and wall thickness, the higher the load capacity and operating pressure, and the higher the weight and cost.

3. Determine the required mounting style and orientation. The mounting style is how the cylinder is attached to your machine or structure, while the orientation is how the cylinder is positioned relative to gravity. It would help if you ensured that the cylinder could be mounted securely and operate smoothly in your desired configuration. The mounting style and orientation affect the cylinder's stress distribution and seal performance. Generally, there are four common mounting styles: trunnion mount, clevis mount, cross tube mount, and eye mount. Individually mounting style includes its advantages and disadvantages, depending on your application.

4. Determine the required seal type and material. The seal type is how the cylinder prevents fluid leakage between its stages and ports, while the seal material is what the seal is made of. It would help if you ensured that the cylinder could maintain its sealing integrity and efficiency under your operating conditions. The seal type and material affect the friction, wear, temperature resistance, chemical resistance, and service life of the cylinder. Generally, there are two main seal types: U-cup and O-ring seals. Each seal type has its pros and cons, depending on your application.

5. Compare different brands and models of double acting telescopic cylinders. Once you have determined your specifications and preferences, you can start looking for different double-acting telescopic cylinder options from various manufacturers and suppliers. You must compare their features, quality, performance, reliability, warranty, price, availability, and customer service. You can also read reviews, testimonials, ratings, feedback, and recommendations from other users or experts who have used or tested them.

By following these steps, you can select the best double acting telescopic cylinder for your application. Always consult a professional engineer or technician before making any final decision or purchase.

Why Choose Orione Hydropower?

Double acting telescopic cylinder for a specific application, one should consider factors such as space availability, load direction, force requirement, stability need, cost budget, weight limit, maintenance frequency, etc.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfill or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and double-acting telescopic cylinder trader in Sikkim, India. These Double acting telescopic cylinders are available across India. Please quote here if you have this product!