- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Single Acting s Suppliers

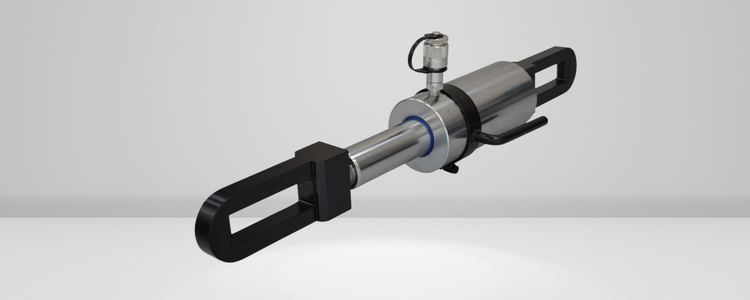

A single acting cylinder is a type of hydraulic cylinder that operates in one direction only. It has one port for the inlet and outlet of hydraulic fluid and a piston rod that extends and retracts as the fluid pressure changes. A single-acting cylinder can be used for various applications, such as lifting, clamping, pressing, or holding.

One of the advantages of a single acting cylinder is that it is simpler and cheaper than a double acting cylinder, which has two ports and can operate in both directions. A single acting cylinder also requires less fluid and space than a double acting cylinder.

Orione Hydropower is a leading manufacturer and supplier of Single acting Cylinders in Haryana, India. Our high-end designs are made of metal to prevent corrosion and withstand wear. As a trusted manufacturer in Haryana, we use only the finest quality materials to deliver the best options to our customers. Please browse our website and place your order according to your preferences.

Capacity 10 - 30 ton / Stroke 150 mm / Max. Working Pressure 700 bar

Technical :

| Capacity (ton) | Capacity (kN) | Stroke (mm) | Model | Effective area (cm2) | Oil cap. (cc) | Extended (mm) | Closed height (mm) | Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 10 | 107 | 150 | OSPC 10-150 | 15.3 | 230 | 691 | 541 | 14 |

| 20 | 225 | 150 | OSPC 20-150 | 32.1 | 485 | 770 | 620 | 28 |

| 30 | 332 | 150 | OSPC 30-150 | 47.4 | 715 | 820 | 670 | 48 |

Features of Single Acting Cylinders

Orione Hydropower is a company that specializes in designing and manufacturing single acting cylinders for various hydropower applications. Orione Hydropower offers a range of single acting cylinders with different sizes, capacities, strokes, and mounting options. Some of the features of Orione Hydropower's single acting cylinders are:

Applications of Single Acting Cylinders

A single acting cylinder is a pneumatic or hydraulic cylinder that uses compressed air or fluid to move the piston in one order and a spring or another external force to return it to its original position. Single acting cylinders are widely used in various industrial applications, such as packaging, clamping, punching, lifting, and pressing.

Orione Hydropower's single acting cylinders can be used for various hydropower applications, such as:

Gate opening and closing

Orione Hydropower's single acting cylinders can be used to control the opening and closing of gates in dams, spillways, or canals. The cylinders can provide fast and precise movement of the gates and withstand the water pressure and flow.

Turbine regulation

Orione Hydropower's single acting cylinders can regulate the speed and power output of turbines in hydropower plants. The cylinders can adjust the angle and position of the blades or vanes in the turbine and cope with the torque and rotation of the shaft.

Penstock control

Orione Hydropower's single acting cylinders can be used to control the flow and pressure of water in penstocks, which are pipes that carry water from the reservoir to the turbine. The cylinders can modulate the opening and closing of valves or butterfly valves in the penstock, as well as handle the water hammer effect.

Packaging

Single acting cylinders are often used in packaging machines, where they perform tasks such as pushing, pulling, sealing, and cutting. For example, a single acting cylinder can be used to make a product into a box, remove a lid over it, fill it with tape, and cut off the excess material. Single acting cylinders are suitable for packaging applications because they are compact, fast, accurate, and efficient.

Clamping

Single acting cylinders are also used for clamping, holding an object in place while another operation is performed on it. For example, a single acting cylinder can connect a metal sheet while drilled, welded, or bent. Single acting cylinders are ideal for clamping applications because they provide a robust and reliable holding force and can be easily controlled by valves.

Punching

Single acting cylinders are also used for punching operations, creating holes or shapes in a material by applying a sudden force. For example, a single acting cylinder can be used to punch holes in a paper sheet or to punch out shapes from a metal plate. Single acting cylinders are effective for punching applications because they deliver a high-impact force quickly and can be adjusted for different stroke lengths and speeds.

Lifting

Single acting cylinders are also used for lifting applications, where they raise or lower an object or a platform. For example, a single-acting cylinder can be used to lift a car jack, an elevator platform, or a dump truck bed. Single-acting cylinders are convenient for lifting applications because they can handle heavy loads with minimal air or fluid consumption and can be mounted in various orientations.

Pressing

Single acting cylinders are also used for critical applications, where they apply pressure or force to an object or a material. For example, a single-acting cylinder can be used to press a button, a switch, or a lever. Single-acting cylinders are helpful for critical applications because they can provide precise and consistent pressure and can be operated by simple mechanisms.

Advantages of Single Acting Cylinders

Some of the benefits of using single acting cylinders are:

However, a single acting cylinder also has some disadvantages, such as:

How To Select The Best Single Acting Cylinder For Your Applications?

Single acting cylinders are hydraulic cylinders that produce force in one direction only. They are simple, reliable, and cost-effective devices used for various applications, such as lifting, clamping, pressing, or punching. However, not all single acting cylinders are the same. Different types, sizes, and specifications must be considered before choosing the best single acting cylinder for your application.

Here are some characteristics to keep in mind:

Type of return

Single acting cylinders can have different types of return mechanisms, such as gravity, spring, or external force. Gravity-return cylinders rely on the weight of the load or the cylinder itself to retract the piston when the pressure is released. Spring-return cylinders use a spring inside or outside the cylinder to push the piston back to its original position. External-force-return cylinders depend on another device, such as a lever or a cable, to pull the piston back. The type of return affects the cylinder's speed, force, and efficiency.

Size and stroke

The size and stroke of a single acting cylinder determine how much force it can generate and how far it can extend or retract. The size refers to the piston's diameter and the cylinder's bore. The stroke relates to the length of travel of the piston. Generally, larger cylinders can produce more force but require more fluid and space. Longer strokes can provide more range of motion, but they also increase the risk of buckling or bending of the piston rod.

Pressure and flow

The pressure and flow of the hydraulic fluid affect the performance and speed of a single acting cylinder. The pressure refers to the force exerted by the liquid on the piston. The flow refers to the rate at which the fluid enters or exits the cylinder. Higher pressure can increase the force output of the cylinder, but it also increases the stress and wear on its components. Higher flow can increase the speed of extension or retraction of the cylinder, but it also requires more power and capacity from the pump and reservoir.

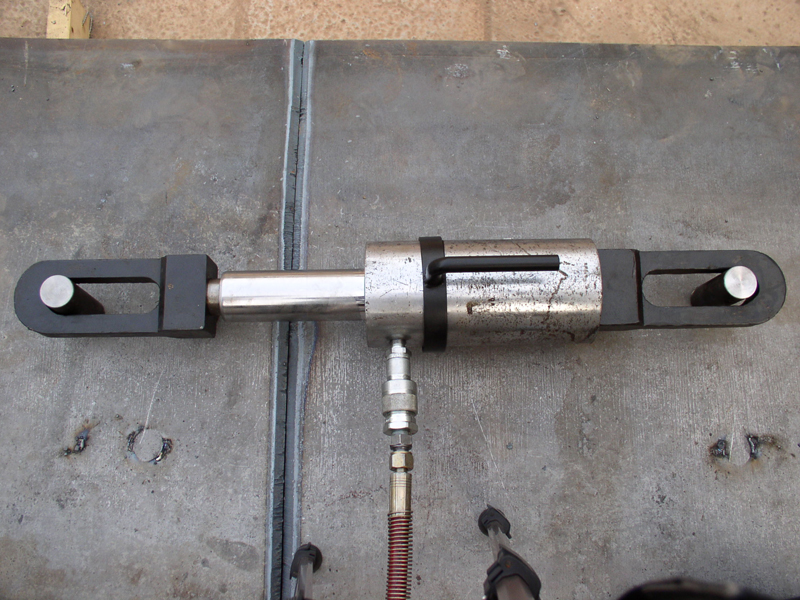

Mounting and alignment

The mounting and alignment of a single acting cylinder affect its stability and durability. The mount refers to how the cylinder is attached to its base or frame. The alignment refers to how well the cylinder is aligned with its load and direction of motion. There are different mounting options for single acting cylinders, such as flange, clevis, trunnion, or foot mounts. The mounting should be sturdy and secure to prevent vibration or movement of the cylinder. The alignment should be precise and consistent to avoid misalignment or side loading of the piston rod.

Application and environment

The application and background of a single acting cylinder affect its suitability and longevity. The application refers to what kind of task or functions the cylinder is used for. The environment refers to what kind of conditions or elements the cylinder is exposed to. Different applications may require different types of single acting cylinders with various features or specifications. For example, some applications may need adjustable cushions, limit switches, or position sensors for better control and safety. Different environments may also affect the performance and lifespan of single acting cylinders. For example, some settings may have high or low temperatures, humidity, dust, corrosion, or contamination that can damage or degrade the cylinder.

Considering these characteristics, you can choose the best single acting cylinder for your application. Single acting cylinders are versatile and efficient devices that can assist you in achieving your goals and improving your productivity.

Why Choose Orione Hydropower?

Single acting cylinders are versatile and efficient devices that perform various tasks in different industrial settings. They offer many benefits over other cylinders regarding cost, size, speed, accuracy, and reliability.

If you are searching for an efficient and trustworthy solution for your hydropower needs, consider Orione Hydropower's single acting cylinders. We have a wide range of single acting cylinders that can meet your specific needs and requirements.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfill or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and trader of Single acting cylinders in Haryana, India. These Single acting cylinders are available across India. Please quote here if you have this product!