- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Telescopic Cylinders Suppliers

A telescopic cylinder is a particular type of hydraulic or pneumatic cylinder that provides a long output travel from a very compact retracted length. It consists of a series of tubes of progressively smaller diameters nested within each other, called stages. The largest tube is the barrel, and the smallest is the plunger or piston rod. Telescopic cylinders are also known as telescoping cylinders or multi-stage telescopic cylinders.

Telescopic cylinders are useful for applications requiring a long stroke but have limited space for the cylinder. For example, they are commonly used in dump trucks, cranes, forklifts, and other heavy-duty vehicles and machines. Telescopic cylinders can provide a high lifting force at the beginning of the stroke when the largest diameter stage is extended and then a smaller force to continue raising the load when the more miniature diameter stages are developed.

Telescopic cylinders can be single-acting or double-acting, depending on whether they extend or retract by fluid pressure or by gravity or external force. Single-acting telescopic cylinders are usually used for applications that only require extension by fluid pressure, such as dump trucks. Double-acting telescopic cylinders are used for applications that require both extension and retraction by fluid pressure, such as cranes.

The design and operation of telescopic cylinders are more complex than conventional cylinders, as they involve multiple seals, ports, and stages. Telescopic cylinders also require careful attention to stability, alignment, and side loading, as they are subjected to enormous forces and moments at full extension. Telescopic cylinders should be selected and installed according to the specifications and recommendations of the manufacturer.

Telescopic cylinders are an innovative and versatile solution for many hydraulic and pneumatic applications that require long strokes in limited spaces. They offer many advantages over conventional cylinders, such as higher efficiency, lower weight, and reduced installation space. However, they have limitations and challenges, such as higher costs, more maintenance, and lower speed. Therefore, telescopic cylinders should be chosen carefully based on the requirements and conditions of each application.

Orione Hydropower is a leading manufacturer and supplier of Telescopic Cylinders in Chhattisgarh, India. Our high-end designs are made of metal to prevent corrosion and withstand wear. As a trusted manufacturer in Chhattisgarh, we use only the finest quality materials to deliver the best options to our customers. Please browse our website and place your order according to your preferences.

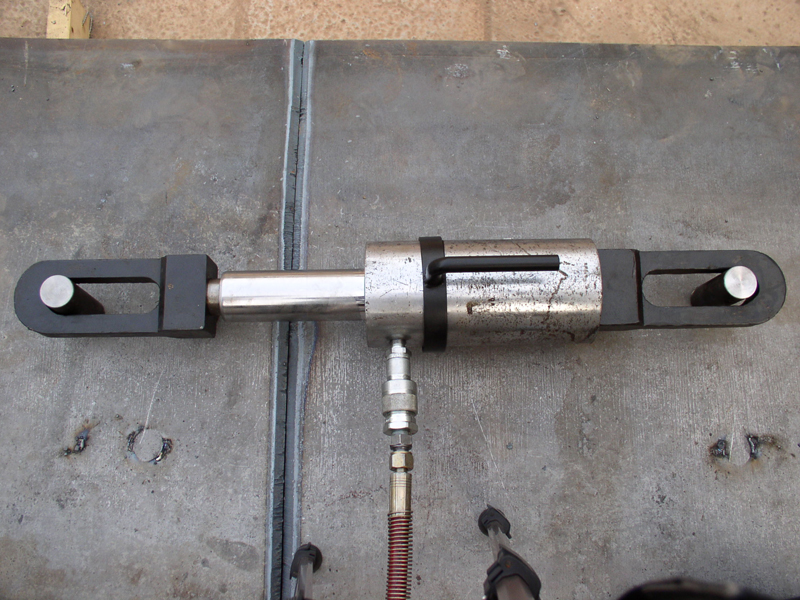

Capacity 10 - 30 ton / Stroke 150 mm / Max. Working Pressure 700 bar

Technical :

| Capacity (ton) | Capacity (kN) | Stroke (mm) | Model | Effective area (cm2) | Oil cap. (cc) | Extended (mm) | Closed height (mm) | Approx Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| 10 | 107 | 150 | OSPC 10-150 | 15.3 | 230 | 691 | 541 | 14 |

| 20 | 225 | 150 | OSPC 20-150 | 32.1 | 485 | 770 | 620 | 28 |

| 30 | 332 | 150 | OSPC 30-150 | 47.4 | 715 | 820 | 670 | 48 |

Features of Telescopic Cylinders

Telescopic cylinders are a type of hydraulic cylinder that can extend and retract to different lengths, depending on the application. They are commonly used in mobile equipment, such as cranes, dump trucks, aerial lifts, and agricultural machinery. Telescopic cylinders have several advantages over conventional cylinders, such as:

Applications of Telescopic Cylinders

A telescopic cylinder is a hydraulic or pneumatic cylinder that consists of multiple stages or sleeves of different diameters that extend or retract in a telescopic manner. This design allows for a long stroke length with a compact retracted length, which is helpful for applications where space is limited but an extensive range of motion is required. Telescopic cylinders are also known as multi-stage telescopic cylinders or simply telescoping cylinders.

Telescopic cylinders can be classified into two types: single-acting and double-acting. A single-acting telescopic cylinder only extends by hydraulic or pneumatic pressure and retracts by gravity or external force. A double-acting telescopic cylinder can extend and reject by hydraulic or pneumatic pressure, which gives more control and flexibility. The number of stages or sleeves in a telescopic cylinder can vary from two to nine, depending on the desired stroke length and load capacity.

Telescopic cylinders have many applications in various industries, such as construction, mining, transportation, agriculture, and material handling. Some examples of telescopic cylinder applications are:

Hydraulic cranes: Telescopic cylinders are used to lift and lower the boom and load of a hydraulic crane. The telescopic design allows for a high lifting height with a low profile when not in use.

Dump trucks: Telescopic cylinders are used to tilt and dump a load. The telescopic design allows for a complete emptying of the bag with a short retracted length.

Forklifts: Telescopic cylinders raise and lower the forks and a forklift load. The telescopic design allows for a high lifting height with a low profile when not in use.

Scissor lifts: Telescopic cylinders are used to extend and retract the scissor arms of a scissor lift. The telescopic design allows for a high lifting height with a small footprint when unused.

Telescopic cylinders are an innovative and efficient solution for applications that require long strokes with limited space. They offer many advantages, such as high load capacity, high speed, low maintenance, and easy installation. However, they also have some challenges, such as stability issues, seal leakage, and alignment problems. Therefore, proper design, selection, installation, and maintenance of telescopic cylinders are essential for optimal performance and safety.

Advantages of Telescopic Cylinders

A telescopic cylinder is a hydraulic or pneumatic cylinder that consists of multiple stages or sleeves of different diameters that extend or retract in a telescoping manner. Telescopic cylinders are widely used in applications that require a long stroke but have limited space for the cylinder, such as cranes, dump trucks, forklifts, etc.

Some of the advantages of telescopic cylinders are:

They can provide a longer stroke than conventional single-stage cylinders with the same retracted length. It allows them to fit in compact spaces and achieve a more excellent range of motion.

They can produce different forces at different extension stages, depending on each step's diameter. It allows them to match the force requirements of the load more efficiently and reduce energy consumption.

They can be designed as single-acting or double-acting, depending on the application. Single-acting telescopic cylinders rely on gravity or external force to retract, while double-acting telescopic cylinders use fluid pressure to extend and retract. Double-acting telescopic cylinders can offer more control and stability than single-acting ones.

They can be customized with various features and accessories, such as valves, sensors, cushions, end caps, mounts, etc., to suit different needs and specifications.

Telescopic cylinders have disadvantages, however. Some of the challenges and limitations of telescopic cylinders are:

Therefore, telescopic cylinders are best suited for applications that require a long stroke but have limited space and do not require high speed or precision. Telescopic cylinders can offer many benefits in terms of versatility, efficiency, and functionality. Still, they also pose some challenges and trade-offs that must be considered carefully before choosing them for a specific application.

How To Select The Best Telescopic Cylinders?

A telescopic cylinder is a type of hydraulic cylinder that consists of several nested tubes that can extend or retract to provide different stroke lengths. Telescopic cylinders are commonly used in applications that require a large amount of force in a limited space, such as dump trucks, cranes, and aerial lifts.

There are many factors to consider when selecting the best telescopic cylinder for your application, such as:

The required stroke length

It is the distance the cylinder needs to extend or retract. The stroke length determines the number and size of the tubes in the telescopic cylinder. Generally, the more tubes, the longer the stroke length, and the higher the cost and weight of the cylinder.

The operating pressure

It is the maximum pressure the cylinder can withstand without damage. The working stress affects the wall thickness and diameter of the tubes in the telescopic cylinder. Generally, the higher the pressure, the thicker and bigger the pipes, and the higher the cost and weight of the cylinder.

The load capacity

This is the maximum force the cylinder can exert or resist. The load capacity depends on the cross-sectional area of the tubes in the telescopic cylinder. Generally, the larger the size, the higher the load capacity, but also, the higher the cost and weight of the cylinder.

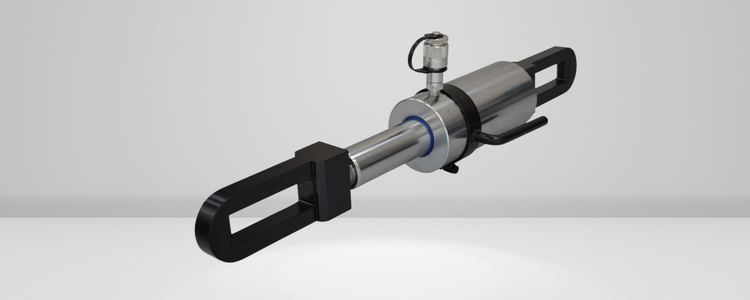

The mounting style

This is how the cylinder is attached to the machine or structure. The mounting style affects the stability and alignment of the cylinder. There are different types of mounting styles for telescopic cylinders, such as trunnion mount, clevis mount, cross-tube mount, and flange mount.

The seal type

This is how the tubes in the telescopic cylinder are sealed to prevent fluid leakage. The seal type affects the efficiency and durability of the cylinder. There are different types of seals for telescopic cylinders, such as O-rings, U-cups, wipers, and wear rings.

To select the best telescopic cylinder for your application, you must balance these factors according to your specific needs and budget. You can consult a reputable manufacturer or supplier of telescopic cylinders for professional advice and recommendations. You can also compare different models and specifications of telescopic cylinders online or in catalogs to find the most suitable one for your application.

Why Choose Orione Hydropower?

Telescopic cylinders are an innovative and versatile solution for many hydraulic and pneumatic applications that require long strokes in limited spaces. They offer many advantages over conventional cylinders, such as higher efficiency, lower weight, and reduced installation space.

Orione Hydropower has built a solid customer base by specializing in application solutions, timely delivery of hydraulic products, and sales service of Hydraulic jacks, Hydraulic Systems, Hydraulic Power Pack, and elements for almost all industries such as Machine Tools, Steel Plants, Cement Industries, Process Industries, Constructions, and OEM.

The organization's primary goal is to provide high-quality, dependable services to industries. The purpose of the product and creating cost-effective solutions that fulfill or surpass our customers' expectations are the focus of our thoughts and activities, not the product itself.

Orione Hydropower is a leading producer, supplier, exporter, and trader of Telescopic Cylinders in Chhattisgarh, India. These Telescopic Cylinders are available across India. Please quote here if you have this product!