- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

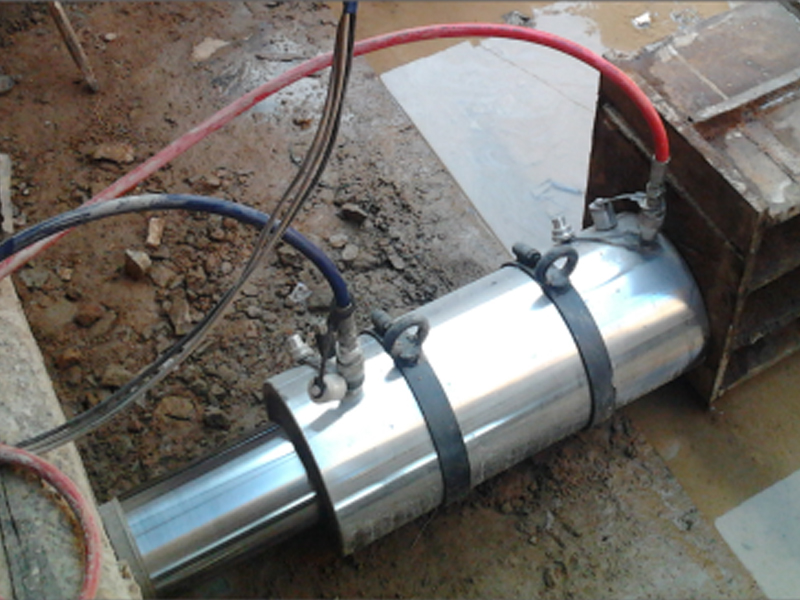

General Purpose Jacks Double Acting Saudi Arabia

When the job calls for strength, consistency, and no surprises—General Purpose Hydraulic Jacks by Orione Hydropower show up ready. These are no-frills workhorses, made with a stainless steel body and a carbon steel plunger. Each unit rolls out with global safety approvals and carries a CE certification. Built to handle 700 bar working pressure, these double acting Hydraulic Jacks don’t back down when put to the test. With bridge repairs and heavy machine lifting, they’re right where the heavy action happens.

What you’re getting is a solid piece of equipment built to stay in the game. Packed in a tough wooden case, each jack arrives with a seals kit so you’re not left hunting for spares. Just open the box, plug into your system, and you’re good to go.

Add to that a 12-month warranty and a separate 1-year cover on core parts. These double acting Hydraulic Jacks are built for people who can’t afford downtime and won’t settle for short-term fixes.

Additionally, versatile Hydraulic lifting equipment units are versatile and powerful and do exactly what they promise. If you’re serious about lifting without limitations, Industrial Hydraulic Jacks from Orione are your answer. Nothing overdone. Just gear that works, round the clock.

General Purpose Jacks Double Acting Overview

When power needs to go both ways, Hydraulic General Purpose Jacks with double acting technology step up to the job. These jacks pull with equal force and give you full control in both directions. That’s why professionals in construction, maintenance, shipbuilding, and heavy machine repair turn to them every time there’s a tough lift on the table. Moreover, the design is no-nonsense. Each jack is engineered with collar threads, base mounting holes, and a threaded plunger—so mounting it, stacking it, or flipping it upside down is never a problem. Long stroke models are available too and helps you lift taller loads without wasting time on extra support setups. Add-ons such as flat or grooved heads (up to 75 tons), tilt saddles, and latch onto the plunger can work while mounted horizontally. What gives these cylinders an edge is their ability to deliver Hydraulic Force in Both Directions. Also, they are ideal when precision matters, like in die lifting, machine positioning, and structural adjustments. Backed by a 700 bar working pressure and ASME B30.1 compliance, these High-Pressure Hydraulic Cylinders are tested for heavy-duty cycles without giving in to stress. The range is massive too with capacities stretching from 10 to 500 tons, and strokes go all the way up to 48 inches. That’s real power packed into a smart design. So, if you’re looking for Double Acting Hydraulic Cylinders that handle serious jobs without flinching, Orione’s got you covered. With double-acting power on both retraction and extension, these cylinders have proved that they are the best machinery. The dual-port setup speeds up cycle times and gives you more action with every press. With industrial pressing lines and massive structural lifts, this range handles the heat with pressure.

Technical Specifications of General Purpose Jacks Double Acting

When it’s time to lift serious weight and retract with the same kind of power, these Double Acting Jack Specifications check all the right boxes. Here’s a breakdown of the numbers that matter to engineers, site heads, and industry experts who don’t have time for anything.

EDX-150 Model – Built for Heavy Hits

- Maximum Operating Pressure: 10,000 psi (700 bar)

- Capacity Class: 150 tons

- Advance Load Capacity: 153.5 short tons

- Retract Load Capacity: 74 short tons

- Stroke Length: 13.13 inches

- Collapsed Height: 22.2 inches

- Extended Height: 35.31 inches

- Material: Heavy-duty steel with corrosion-resistant paint

EDX-250 Series

- EDX-2502T: Stroke 1.97 in, Capacity 279T/115T

- EDX-2506T: Stroke 5.91 in

- EDX-25012T: Stroke 11.81 in

EDX-200 Series

- EDX-2002T: Stroke 1.97 in, Capacity 203T/97T

- EDX-2006T & 20012T: Stroke 5.91 in & 11.81 in

| Capacity (ton) |

Capacity (kN) |

Stroke (mm) |

Model | Effective area (cm2) |

Oil cap. (cc) |

Closed height (mm) |

Wt. (Approx.) (kg) |

|---|---|---|---|---|---|---|---|

| 10 | 111 | 150 | ODP 10-150 | 15.9 | 239 | 275 | 8 |

| 15 | 167 | 150 | ODP 15-150 | 23.8 | 356 | 280 | 10.5 |

| 20 | 218 | 150 | ODP 20-150 | 31.2 | 468 | 285 | 14.2 |

| 25 | 270 | 150 | ODP 25-150 | 38.5 | 577 | 295 | 14 |

| 30 | 309 | 150 | ODP 30-150 | 44.2 | 663 | 305 | 16 |

| 50 | 550 | 150 | ODP 50-150 | 78.5 | 1178 | 305 | 25.5 |

| 75 | 792 | 150 | ODP 75-150 | 113.1 | 1696 | 305 | 36.5 |

| 100 | 1077 | 150 | ODP 100-150 | 153.9 | 2309 | 310 | 52.5 |

| 150 | 1589 | 150 | ODP 150-150 | 227 | 3405 | 320 | 83 |

| 200 | 2199 | 150 | ODP 200-150 | 314.2 | 4712 | 345 | 114 |

| 250 | 2661 | 150 | ODP 250-150 | 380.1 | 5702 | 350 | 145.5 |

| 300 | 3167 | 150 | ODP 300-150 | 452.4 | 6786 | 365 | 179 |

| 400 | 4008 | 150 | ODP 400-150 | 572.6 | 8588 | 385 | 257 |

| 500 | 4948 | 150 | - | 706.9 | 10603 | - | - |

| 600 | 5987 | 150 | - | 855.3 | 12829 | - | - |

| 800 | 7939 | 150 | - | 1134.1 | 17012 | - | - |

| 1000 | 9930 | 150 | - | 1418.6 | 21279 | - | - |

| 1500 | 15154 | 150 | - | 2164.8 | 32472 | - | - |

| 2000 | 20458 | 150 | - | 2922.5 | 43837 | - | - |

| Capacity (ton) |

Capacity (kN) |

Stroke (mm) |

Model | Effective area (cm2) |

Oil cap. (cc) |

Closed height (mm) |

Wt. (Approx.) (kg) |

|---|---|---|---|---|---|---|---|

| 10 | 111 | 150 | ODPS 10-150 | 15.9 | 239 | 285 | 8.2 |

| 15 | 167 | 150 | ODPS 15-150 | 23.8 | 356 | 290 | 10.7 |

| 20 | 218 | 150 | ODPS 20-150 | 31.2 | 468 | 300 | 14.5 |

| 25 | 270 | 150 | ODPS-25-150 | 38.5 | 577 | 310 | 14.3 |

| 30 | 309 | 150 | ODPS 30-150 | 44.2 | 663 | 320 | 16.5 |

| 50 | 550 | 150 | ODPS 50-150 | 78.5 | 1178 | 320 | 26.5 |

| 75 | 792 | 150 | ODPS 75-150 | 113.1 | 1696 | 330 | 37.5 |

| 100 | 1077 | 150 | ODPS 100-150 | 153.9 | 2309 | 330 | 54 |

| 150 | 1589 | 150 | ODPS 150-150 | 227 | 3405 | 345 | 85.5 |

| 200 | 2199 | 150 | ODPS 200-150 | 314.2 | 4712 | 370 | 117.5 |

| 250 | 2661 | 150 | ODPS 250-150 | 380.1 | 5702 | 385 | 150.5 |

| 300 | 3167 | 150 | ODPS 300-150 | 452.4 | 6786 | 400 | 188 |

| 400 | 4008 | 150 | ODPS 400-150 | 572.6 | 8588 | 425 | 268 |

| 500 | 4948 | 150 | ODPS 500-150 | 706.9 | 10603 | 450 | 365 |

| 600 | 5987 | 150 | ODPS 600-150 | 855.3 | 12829 | 480 | 450 |

| 800 | 7939 | 150 | ODPS 800-150 | 1134.1 | 17012 | 515 | 645 |

| 1000 | 9930 | 150 | ODPS 1000-150 | 1418.6 | 21279 | 560 | 868 |

| 1500 | 15154 | 150 | ODPS 1500-150 | 2164.8 | 32472 | 620 | 1534 |

| 2000 | 20458 | 150 | ODPS 2000-150 | 2922.5 | 43837 | 705 | 2357 |

Features and Benefits

When it comes to serious lifting, pressing, or holding power, Hydraulic Jack features become essentials. The General Purpose EDX Series Double Acting Jacks pack in everything that industrial-grade jobs demand, down to the smallest detail.

What Makes These Jacks Stand Out?

Dual Threaded Advantage: Collar and plunger threads save time, get precise alignment, and get working faster.

Armor-Like Finish: Each jack is coated in a high-grade baked enamel that pushes back against corrosion, even in the roughest conditions. So, you'll get grit, grime, and moisture.

Plunger Protection That Counts: Removable hardened saddles reduce wear and tear during every lift. Swap them out fast when needed and there will be no deep tools or special training required.

Over-Pressure? Not On Our Watch: An internal safety valve acts like your silent guardian. It prevents overloads and pressure spikes from turning into downtime or damage.

Clean Cylinders and Long Life: Plunger wipers help block dust, debris, and metal shavings. Less contamination means longer running time without costly rebuilds.

Quick Connect Every Time: Every jack includes a CR400 coupler comes with dust caps to keep operations clean and connection easy.

Engineered to Handle What Others Can’t

If the alloy steel is hardened, it will guide rings and prevent plunger over-travel.

U-cup seals are industrial-grade and stop leaks before they start.

Hardened and chrome-plated pistons cut down on wear and corrosion.

A high-strength alloy steel body holds up to heavy use and long shifts without losing strength.

Internal composite bearings will support off-center loads, decrease friction, and even keep the cylinder walls out of any harm.

Further, optional tilt saddles give better backup if side-load angles remain unavoidable.

These durable Hydraulic Jacks are built tough and made for long-term field use. From planned lifts to unpredictable loads, the advantages of Double Acting Jacks like these are all about putting power, safety, and consistency in your corner.

Applications Across Industries

When precision lifting and controlled force are non-negotiable, Double Acting Jacks in Industries do the heavy lifting. Their power, repeatability, and push-pull control make them indispensable across several high-demand sectors.

Places Where These Jacks Make an Impact

Construction Sites: Jacks will help in bridge positioning, beam alignment, and structural lifting. These construction Hydraulic Jacks will handle shifting tons of concrete and steel with accuracy. Also, it will keep schedules tight and cranes out of overwork.

Railway Maintenance & Track Alignment: Rail engineers rely on them to lift and adjust bogies. With jacks, you can align tracks and handle mid-operation lifting during repairs.

Automotive and Heavy Vehicle Workshops: Automotive Lifting Equipment is made for servicing trucks, trailers, and military vehicles. With axle lifts and frame adjustments, the double-acting mechanism also keeps control at your fingertips in both directions.

Shipbuilding & Marine Yards: These jacks will pull the high weight when ship hulls, large engines, or heavy sections need positioning without trial and error.

Mining and Earthmoving Equipment Maintenance: Machines don’t get bigger than this. These jacks step up when haul trucks or loaders need underbody access or suspension work—where ordinary lifts just won’t cut it.

Industrial Machinery Installation: For precise lifting during machinery placement, leveling, or removal. So, you'll require no cranes because just compact and high-tonnage force will be there right where you need it.

If it's shifting 200 tons of concrete or adjusting a ship’s rudder assembly, Hydraulic Jacks Applications are far from one-size-fits-all. These jacks earn their place in the toolkit as they are powerful, reliable, and ready for the real grind across various sectors.

Why Choose Orione Hydropower in Saudi Arabia

When the job demands muscle and accuracy, a trusted Hydraulic Jack supplier delivers with gear built to handle real pressure. At Orione Hydropower, we are here for heavy lifts, tough angles, and jobs that don’t come with second chances. From shipyards to metro sites, our jacks are already putting in the hours. They hold their ground, stroke after stroke, and day after day.

What Makes It Different?

Precision Runs in Our DNA: Every component is machined for strength and purpose. Our high-quality Hydraulic equipment is designed to take on tonnage. Moreover, it is built using hardened alloy steel, corrosion-resistant finishes, and wear-proof seals that last.

Made for Your Own Workload: It's true that no projects are similar to each othet. That’s why we offer customized Hydraulic solutions. Also, it's built with your load limits, operation type, and industry conditions in mind. If it’s a narrow space lift or high-tonnage push-pull operation, we’ll get it just right.

Consistency: If it's the factory floor or on-site maintenance zones, our jacks will still stand up to the harshest conditions. We, as a reliable Double Acting Jacks manufacturer, prioritize tough builds and proven performance.

Best Support: We stay connected rather than shipping boxes. Our team is ready to advise, guide, and deliver what your site demands without long waits or vague answers.

At Orione, we don’t just manufacture jacks—we back you with decades of hands-on experience and quality you can actually feel in the grip of every lift. So if you're looking for the kind of gear that shows up, holds strong, and keeps working, you’ve just found your supplier.

Frequently Asked Questions

- What are the common difference between double-acting and single acting jacks?

Here’s a quick comparison:

Double-acting: It has two ports: one to push the piston out and the other to bring it back in using fluid pressure. This setup helps in lifting for heavier loads and tighter control.

Single-acting: Such jacks come with a port in which fluid pushes the piston out and it retracts by gravity or an external load. - What are the most common functions of a double-acting cylinder and jacks?

It delivers force in both directions for pushing and pulling. This lets you lift, press, or shift loads with solid grip and faster retraction, making it a favorite for automation lines, presses, and heavy-lift scenarios. - What is a double-acting jack?

A double-acting jack uses hydraulic power to push and pull the piston in both directions with no springs involved. It comes with two ports, which means you can send fluid to either side for smooth movement both ways. - What is one drawback of double-acting jacks?

Here are the major disadvantages of general purpose jacks that are double acting:

They require a full hydraulic circuit with directional valves.

They’re a bit bulkier compared to single-acting ones.

Initial setup can cost more.

But for those who rely on precision and power, the trade-off is often worth it. - How do I take care of my double-acting jack?

You must create a routine checkup in the following manner:

Inspect seals for wear or leaks.

Keep with clean hydraulic fluid as dirt can be its enemy.

Store it in a dry space, away from corrosion threats.

So, these simple maintenance of double acting jacks tips will go a long way in extending service life. - What advice to follow before using hydraulic jacks?

The load must always match the jack’s capacity. Later, you can even use a flat, stable base and never overload. These basic hydraulic jack usage tips make a big difference in safety and performance.