- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Hydraulic Torque Wrench Suppliers in Saudi Arabia

In the never-stopping world of industrial upkeep & assembly, accuracy is non-negotiable. Hydraulic torque wrenches have turned out to be as pivotal industrial torque tools. It delivers the controlled force needed for accurate & repeatable tightening of heavy-duty fasteners. These devices are made to apply a fixed amount of torque to bolts & nuts. It reduces the risk of over-tightening or under-tightening. It is a paramount factor in industries like oil & gas, power generation as well as heavy machinery assembly.

Manufacturers such as Orione Hydropower have advanced the development of hydraulic torque wrenches by integrating user-centric features such as high-speed operation, feather-light design as well as enhanced torque accuracy. These tools are not only strong & reliable but also accomplished enough to adapt to a variety of bolting scenarios.

As part of broader accuracy bolting equipment & torque control solutions, hydraulic torque systems guarantee joint integrity & operational safety in high-pressure scenarios. Their role in minimizing downtime, improving productivity, and ensuring compliance with industry standards cannot be overstated. Whether in routine maintenance or critical infrastructure projects, hydraulic torque wrenches stand out as indispensable assets for technicians and engineers striving for performance and precision.

Product Overview

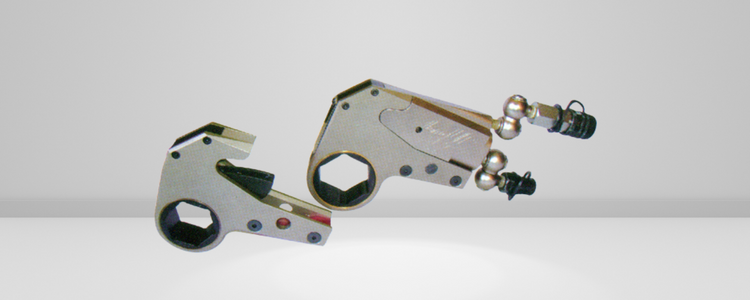

Hydraulic torque wrench Saudi Arabia systems are specialized hydraulic bolting tools designed to deliver controlled & repeatable torque to industrial fasteners. These machineries are vital in applications where accuracy & safety are paramount. It is important particularly in industries such as oil and gas, power generation, mining, construction as well as manufacturing. These are built to handle the most demanding bolting scenarios. Hydraulic torque wrenches offer both power as well as accuracy which makes them indispensable in high-torque operations.

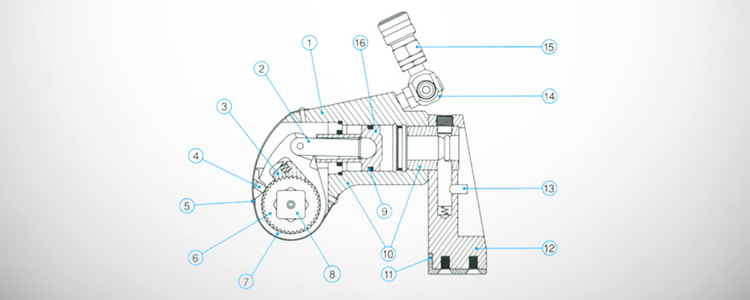

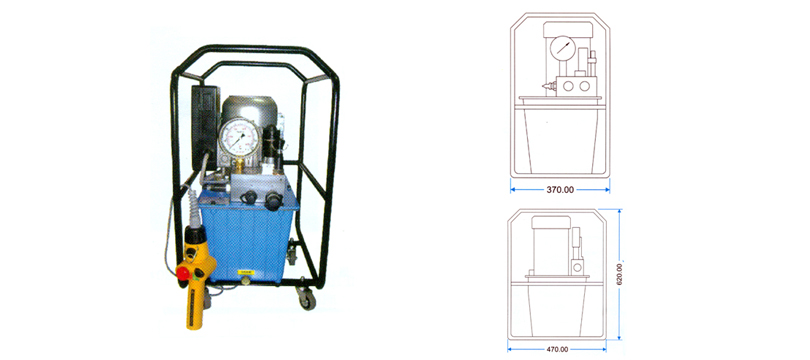

A typical hydraulic torque wrench is inclusive of a hydraulic cylinder, drive mechanism & reaction arm. When pressurized hydraulic fluid is introduced, it activates the cylinder, which in turn powers the drive mechanism. This creates a smooth and calibrated torque output, while the reaction arm ensures counterforce stability during operation. This torque wrench mechanism ensures even load distribution and eliminates bolt stress caused by uneven tightening.

Brands like Orione Hydropower have refined these systems with features or new tech such as compact designs for tight spaces, quick-release couplings, corrosion-resistant materials, and integrated safety locks. Orione Hydropower, in particular, emphasizes innovation in operator safety and tool durability, offering models that are compatible with a variety of power packs and sockets, extending the utility across multiple torque wrench applications.

Hydraulic torque wrench in Saudi Arabia systems are commonly used in flange bolting, heat exchanger upkeep, pipeline assembly & also in other heavy-duty industrial assemblies. Their ability to deliver accuracy torque decreases equipment failure risks, increases structural integrity as well as workplace efficiency. With increasing emphasis on accuracy, precision & safety, these machines continue to evolve with great tech. Now they offer smarter solutions through advanced materials, digital controls & ergonomic design.

Whether for daily upkeep tasks or very important infrastructure installations, hydraulic torque wrenches remain a vital organ in the toolkit of pro personnels who demand uncompromised performance along with control.

Technical Specifications of Hydraulic Torque Wrenches

Understanding the hydraulic torque wrench Saudi Arabia specifications is so significant for choosing the right machines for industrial tasks that demand both power & accuracy. These tools are engineered to deliver consistent and repeatable torque across a broad range of heavy-duty bolting applications. Manufacturers such as Orione Hydropower provide extensive & amazing details to ensure professionals can match the right model to the required performance.

At the bottom of every hydraulic torque wrench lies its torque output range. This generally varies from 100 Nm to over 80,000 Nm, depending on the model and application. This humongous range enables the tool to serve in both light maintenance tasks & massive structural assemblies. Hydraulic pressure ratings typically range from 700 to 1,500 bar (10,000 to 21,750 psi), facilitating high-torque delivery with lesser physical exertion.

Accuracy and Trust are increased more and more through internal gear mechanisms, zero-backlash drives, and multi-tooth pawl systems. Advanced units from TorcUP Inc. are all inclusive of anti-lock drive systems & calibrated tolerances to deliver ±3% torque accuracy. Similarly, Orione Hydropower offers models with lightweight aluminum alloy bodies, high-cycle seals, and corrosion-resistant finishes to ensure durability and low maintenance.

These machines or devices also feature varying drive options. Some options are like square drive & low-profile configurations. Each is suited to specific environments. Low-profile variants are particularly useful for compact spaces and flange applications, whereas square drive models offer flexibility with interchangeable sockets. Stroke length, reaction arm adaptability as well as multi-position handle designs further increases usability and operator comfort.

Quick-connect couplings & swivel manifolds on many models guarantee ease of hydraulic line attachment as well as improved mobility during operation. Some models also support dual-port operation for simultaneous tightening, speeding up the workflow.

In summary, hydraulic torque wrench performance hinges on a mix of torque range, pressure capacity, mechanical precision & ergonomic design. When chosen according to accurate technical needs, these devices offer unmatched performance, safety as well as efficiency in industrial bolting operations.

Features and Benefits of Hydraulic Torque Wrenches

The advantages of hydraulic torque wrenches lie in their ability to deliver accurate, repeatable torque while maintaining operator freedom along with tool longevity. These quality performance tools are essential in industries where consistent bolt tensioning & joint integrity are non-negotiable. Leading manufacturers like Orione Hydropower have developed feature-rich devices made to meet the rigorous & very big demands of industrial bolting.

One of the most important torque wrench features is torque accuracy. Most hydraulic models provide an accuracy rate of ±3%, ensuring uniform bolt load across joints & also eliminating issues caused by uneven tightening. This makes them ideal for very important applications such as flange connections, pressure vessel assembly & structural bolting.

Durability is another defining trait of these devices. Brands like Orione Hydropower offer durable torque tools with high-strength aluminum as well as alloy steel bodies, corrosion-resistant coatings, and robust internal mechanisms. These features reduce wear & also extend the service life of the wrench even in harsh operating environments such as offshore rigs, shipyards & sometimes power plants.

Ease of use is also a priority. Ergonomic design elements, including compact profiles, 360-degree swivel couplings, and multi-position handles, improve operator control and comfort during extended use. Tools from Orion are especially noted for quick setup, lightweight construction & also user-friendly interfaces that diminish training time along with operational errors.

Versatility is a standout benefit—hydraulic torque wrenches come in both square drive and low-profile versions, allowing technicians to work in tight spaces and on various bolt sizes. Compatibility with different hydraulic power packs & also interchangeable accessories further extends application flexibility.

Finally, these machines support precise bolting solutions by reducing reliance on manual torque guesswork. The use of controlled hydraulic pressure allows for predictable torque output, which boosts safety, reduces downtime, and improves assembly quality.

In essence, hydraulic torque wrenches are not only powerful but also smart investments when it comes to unmatched precision, longevity & operational efficiency in bolting tasks.

Applications Across Industries

The scope of hydraulic torque wrenches applications further moves across a wide series of heavy industries. Industries where accuracy, freedom along with efficiency in bolting operations are mission-critical. These high-torque devices are very beneficial in guaranteeing the structural integrity of large machinery, critical infrastructure as well as high-pressure systems. From energy production to infrastructure development, torque tools in industries help professionals achieve consistent and secure fastening every time.

In the oil & gas sector, hydraulic torque wrenches are widely used. You know why? As oil and gas bolting equipment for pipeline connections, refinery maintenance & also pressure vessel assembly. The ability to apply precise torque ensures leak-proof seals and reliable joint integrity, which are vital in high-risk, high-pressure environments.

In power generation, especially in wind, hydro & nuclear plants, these products are used to tighten bolts in turbines, generators & structural components too. Precision torque application helps decrease downtime & also guarantee adherence with regulatory standards.

In the construction industry, construction torque solutions play a vital role in assembling steel frameworks, bridges, and heavy machinery. Hydraulic wrenches offer the strength & control needed for bolting large structural joints even in compact or close spaces.

Mining & heavy equipment sectors rely on these devices for maintaining haul trucks, crushers as well as earthmovers. With continual & high-load operations, the precision & strength of hydraulic torque wrenches decrease wear along with mechanical failures.

Shipbuilding, aerospace & also manufacturing industries use these products for their ability to deliver uniform torque in complex assemblies, improving safety and extending component life.

Manufacturers like Orione Hydropower offer specialized wrench systems designed to meet the specific demands of each industry. Their versatility & strong layout make hydraulic torque wrenches indispensable across sectors. They deliver reliability & accuracy where it matters most.

Why Choose Orione Hydropower

When it comes to dependable and high-performance hydraulic torque solutions, Orione Hydropower stands out as a trusted hydraulic torque wrench manufacturer with a proven track record of quality, innovation, and customer satisfaction. With decades of experience in the hydraulic tools industry, Orione has established itself as a reliable torque solutions provider for a wide spectrum of industrial sectors, including oil and gas, construction, power generation, and heavy equipment maintenance.

What sets Orione apart is its unwavering commitment to delivering high-quality bolting tools that combine durability, precision, and ergonomic design. Each product is built to conform to international quality and safety standards, ensuring optimal performance even in the most demanding environments. From design to delivery, every torque wrench is subject to rigorous testing as well as quality control. It reflects the brand’s promise of long-term reliability along with operational efficiency.

Orione Hydropower also excels in developing customized torque systems to meet the specific requirements of unique industrial applications. Whether clients need compact low-profile tools for confined spaces or high-torque systems for huge structural assemblies, Orione’s in-house engineering abilities make well-curated solutions possible without compromising on performance or safety.

Backed by a knowledgeable technical support team and a strong after-sales service network, Orione guarantees that its users receive not just a product, but a complete torque management solution. Drawing inspiration from industry leaders like TorcUP Inc., Orione continues to invest in R&D to incorporate the latest technologies and materials into their toolsets.

For industries seeking accuracy, reliability along with long-term value, Orione Hydropower is more than just a manufacturer. It is a strategic partner in achieving bolting excellence. Their focus on quality craftsmanship and application-specific innovation makes them a go-to name for reliable torque solutions worldwide.

Frequently Asked Questions (FAQs)

1. What are hydraulic torque wrenches employed in?

Hydraulic torque wrenches are used for applying a fixed & precise amount of torque to a fastener, usually a bolt or a nut. They are particularly used in industries where large bolts must be tightened with high care & precision. These sectors are such as oil and gas, power generation, mining, construction as well as transportation too.

2. How do hydraulic torque wrenches work?

These items use hydraulic pressure to make torque. Pressurized fluid from a hydraulic pump drives a piston in the wrench, which transfers force through a ratcheting mechanism to the fastener. This process allows for controlled & also repeatable torque application.

3. What are the benefits of using hydraulic torque tools over manual tools?

Hydraulic torque wrenches offer significantly greater torque output, accuracy, and repeatability compared to manual tools. They reduce physical strain, improve safety, and ensure consistent tightening in high-stakes applications.

4. Are there different ranges of hydraulic torque wrenches?

Yes. The two most common ranges or series are square drive & low-profile ones. Square drive models are adaptable & used with interchangeable sockets. On the contrary low-profile machines are designed for tight clearance applications.

5. What factors should be considered when choosing a hydraulic torque wrench?

Major factors include the torque range needed, needed clearance around the bolt, application type, frequency of use as well as rapport with pre-exquisite hydraulic systems.

6. What are some torque wrench usage tips?

Always verify torque settings, use the correct accessories, check for damage before use & also follow the manufacturer’s guidelines. Using calibrated devices makes sure precise results & prevents over-tightening or under-tightening.