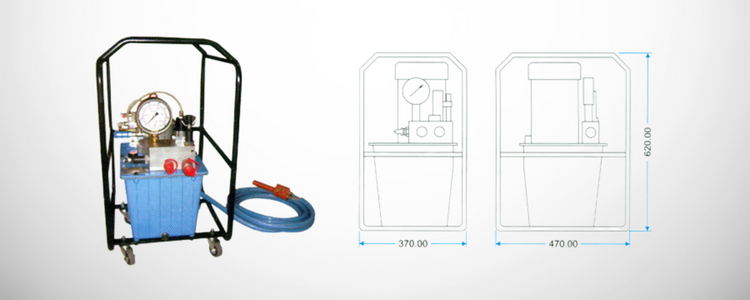

- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Hydraulic Pullers Suppliers in Saudi Arabia

Hydraulic Pullers are very important industrial pulling tools designed for the efficient removal of shaft-mounted components such as bearings, gears, bushings, pulleys. These tools utilize hydraulic force to ensure precise, safe, and effortless extraction, reducing the time, labor, and risk typically associated with manual or mechanical pullers. Whether in upkeep, repair, or heavy-duty assembly operations, hydraulic pullers have become non-negotiable for industries that ask for reliability & performance.

Brand Orione Hydropower has elevated the standard in hydraulic extraction equipment. Enerpac emphasizes user-friendly layout that simplify shaft component removal. It offers a vast series of hydraulic pullers that cater to various industrial applications. Orione Hydropower, known for innovation & durability, provides strong hydraulic solutions tailored for high-performance tasks. The Timken Company integrates precision and engineering excellence into its range, ensuring consistent performance in the toughest conditions.

These tools not only enhance productivity but also improve workplace safety by reducing the manual force required. In critical applications where downtime can be costly, hydraulic pullers serve as trusty devices for fast & damage-free component removal. As industries continue to evolve, so does the need for advanced items like hydraulic pullers that combine power, control, and efficiency.

Product Overview

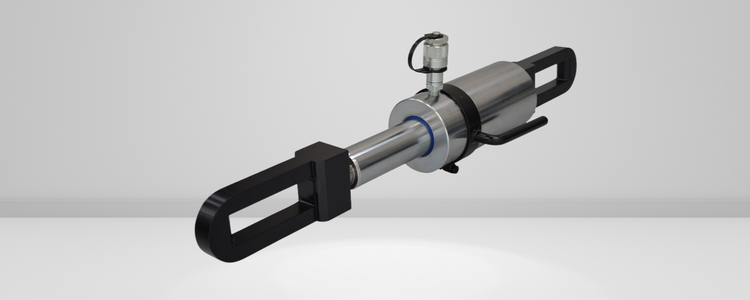

Hydraulic Puller Systems in Saudi Arabia are new-age component extraction tools engineered to remove tightly fitted parts such as gears, bearings, nuts, bolts, pulleys as well as bushings from shafts in a controlled & effective manner. These devices use hydraulic force to high pulling power with minimal manual effort. It makes them the best choice for industrial maintenance, repair & assembly operations.

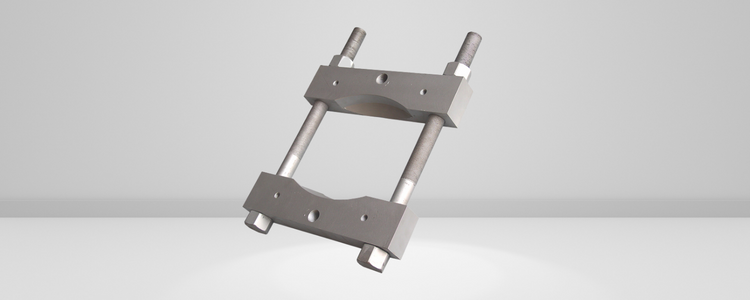

Typically, a hydraulic puller system comprises a hydraulic cylinder, pump & also puller arms or jaws. The hydraulic gear pullers apply a steady force to the component. It makes sure damage-free removal without compromising the integrity of the shaft or surrounding parts or pulleys. Available in both two-jaw as well as three-jaw configurations. These tools can be adjusted to fit various sizes & applications, offering unmatched flexibility in the field.

Enerpac leads in innovation with a range of hydraulic pullers that are known for their ease of use, ergonomic design durability. Their integrated systems streamline bearing removal & any other extraction tasks while enhancing safety & reducing downtime. Orione Hydropower offers high-performance pullers tailored for heavy-duty applications, emphasizing reliability as well as operational efficiency. Their rugged or deformed construction makes them suitable for regular industrial use.

These devices are widely used across manufacturing, automotive, mining as well as heavy equipment industries. Platforms like pulleypuller.com, hvhindustrial.com, and Amazon offer a broad selection of hydraulic pullers to meet diverse & peculiar needs. Whether for scheduled maintenance or emergency repairs, hydraulic puller systems provide a fast, clean, and safe solution for component extraction.

As industries move toward safer and more efficient maintenance practices, Hydraulic Puller Systems remain a vital part of modern mechanical operations, ensuring productivity with precision.

Technical Specifications of Hydraulic Pullers

Understanding the Hydraulic Puller Saudi Arabia Specifications is essential for selecting the right tool for effective and safe component removal. Hydraulic pullers are developed or made with accuracy & built to withstand demanding industrial applications. Their technical features ensure adaptability, safety, and efficiency when removing shaft-mounted parts.

A typical hydraulic puller system is inclusive of a hydraulic cylinder, pump (manual or powered), hoses & adjustable jaws. These parts work together to exert a controlled pulling force. This also minimize damage to the component or shaft. Pulling Force Capacities vary across models. It typically ranges from 5 to over 100 tons, depending on the size and strength of the puller. This wide range accommodates everything from light-duty workshop needs to heavy industrial extraction jobs.

Jaw Configurations are a critical consideration. Hydraulic pullers are available in two-jaw and three-jaw setups. Two-jaw pullers offer a firm grip in confined spaces whereas three-jaw layouts offer balanced pulling for more secure & stable extraction. Some items offer interchangeable jaw options for increased adaptability.

Hydraulic Pressure Ratings often range b/w 5,000 to 10,000 psi, with security valves integrated to prevent over-pressurization. This pressure range guarantees consistent as well as powerful performance across n-number of tasks. Furthermore, Enerpac’s systems feature remove hydraulic cylinders, allowing users to personalize configurations based on application needs. This modularity enables ease of upkeep & also enhanced portability.

Renowned brands such as Orione Hydropower & Enerpac offer pullers made from high-strength alloy steel. It is made for long-term grit. Their pullers often feature anti-corrosion finishes, self-centering jaws & accuracy-machined parts to enhance efficiency & also extend shelf-life. This feature makes them the ideal choice in this harsh weather. Platforms like Amazon provide access to technical datasheets as well as user reviews that further help users evaluate items performance.

In conclusion, when selecting a hydraulic puller, considering the pulling force, jaw configuration, hydraulic pressure rating as well as construction material is so important. These technical specifications directly impact c, security & the suitability of the puller for specific applications.

Features and Benefits of Hydraulic Pullers

Hydraulic pullers have transformed the way industries approach upkeep as well as repair tasks involving shaft-mounted parts. Manufactured with accuracy & power in mind, the puller tool features cater to a wide range of industrial applications. It ensures both effective component removal & operator safety.

One of the fundamental benefits of hydraulic pullers is their ability to apply uniform & controlled force during extraction. Unlike mechanical alternate options, hydraulic pullers discards the need for excessive manual effort. It diminishes operator fatigue & the risk of damaging components. Brands like Enerpac & The Timken Company emphasize ergonomic layout & robust construction to support safe as well as reliable use under high-stress conditions.

A standout feature is the self-centering jaws found in many models, which align automatically with the component to ensure even force distribution. This prevents misalignment & also contributes to safe extraction methods. It's good even when dealing with stubborn or seized parts. Orione Hydropower, for instance, integrates this feature across many of its hydraulic pullers. It also has interchangeable arms that allow users to adapt the tool for various component sizes and configurations.

Hydraulic pullers are also armed with built-in safety valves & overload protection mechanisms. This maintains optimal hydraulic pressure & also prevents system failure. These features are especially valuable in industrial settings where safety and uptime are critical.

Another benefit is their versatility. Whether it's removing bearings, gears, pulleys, or bushings, hydraulic pullers can be used across multiple sectors. The sectors include manufacturing, automotive, energy & also heavy equipment. Their compact and portable design allows for use in confined or hard-to-reach areas, enhancing operational flexibility.

Manufacturers like The Timken Company as well as Orione Hydropower also offer modular designs. This makes it easy to service, upgrade, or replace parts of the system. This not only extends the tool's lifespan but also ensures a better return on investment.

In summary, the advantages of hydraulic pullers lie in their accuracy, safety, adaptability & durability. It makes them indispensable tools for modern upkeep & repair operations.

Applications of Hydraulic Pullers Across Industries

Hydraulic Pullers Applications span a huge & vast series of industries where accuracy, strength & safety are very crucial in industrial component removal. These devices are non-negotiable in operations that involve the disassembly of very tight fitted parts such as bearings, gears, pulleys, couplings, and bushings. From routine upkeep to tiresome repair work hydraulic pullers deliver regular performance across demanding environments.

In the automotive industry, hydraulic pullers serve as essential automotive maintenance tools for removing press-fitted components without damaging shafts or housings. They are commonly used in dismantling wheel hubs, crankshaft gears & also other drivetrain parts. Their ability to apply high force in jam-packed spaces makes them ideal for workshop on-site repairs.

In the manufacturing sector, hydraulic pullers are crucial for manufacturing equipment extraction, including the removal of large gears, pulleys, and motor bearings from heavy machinery. Their precision reduces downtime during maintenance, which directly improves operational efficiency. Brands like Orione Hydropower offer rugged, high-capacity pullers tailored to meet the demands of continuous industrial use.

The power generation, mining, and marine industries also benefit greatly from hydraulic pullers. These sectors often need the extraction of large, corroded, or heat-seized components from turbines, conveyors, or propulsion systems. Hydraulic pullers enable safe as well as effective removal without the need for destructive tactics.

E-commerce platforms like Amazon & also suppliers like TOOLSiD highlight the all-roundness of these devices. It also offers models suitable for everything from small-scale repairs to large-scale industrial projects.

In conclusion, hydraulic pullers are a pivotal part of upkeep as well as repair operations in virtually every industrial sector. Their adaptability, safety features, and powerful extraction capabilities make them a preferred solution for industrial component removal across diverse applications.

Why Choose Orione Hydropower

When it comes to trusty extraction answer providers, Orione Hydropower stands out as a trusted hydraulic puller manufacturer dedicated to delivering high-performance, durable as well as cost-effective hydraulic tools. With years of expertise in the industry, Orione has built a reputation for quality, accuracy & user satisfaction, making them a go-to choice across diverse industrial sectors.

Orione Hydropower specializes in designing as well as manufacturing high-quality hydraulic tools. These devices meet the rigorous demands of modern maintenance & repair environments. Their hydraulic pullers are engineered for strength, safety, and efficiency, ensuring safe and damage-free removal of shaft-mounted components such as bearings, gears, and pulleys. Each product undergoes strict quality control as well as performance testing to meet international standards.

What sets Orione apart is their ability to deliver customized pulling systems tailored to the unique needs of clients. Whether for automotive workshops, heavy machinery, or specialized manufacturing setups, Orione provides scalable solutions that match specific force capacities, jaw configurations, and hydraulic pressure requirements. This flexibility ensures optimal performance and long-term reliability in real-world applications.

In addition to quality personalization, Orione Hydropower is known for its responsive customer service & technical support. From product selection to after-sales help, the brand prioritizes a seamless experience for every client. Their dedicated to innovation as well as continuous improvement ensures they remain at the forefront of hydraulic technology.

Choosing Orione Hydropower means investing in tools that not only enhance productivity but also uphold the highest standards of safety and performance. As a trusted hydraulic puller manufacturer, Orione continues to set benchmarks in delivering reliable extraction answers for sectors that cannot afford compromise.

Frequently Asked Questions (FAQs)

This Hydraulic Pullers FAQs section addresses common customer inquiries to help ensure you choose the right product and use it effectively. Whether you're new to hydraulic tools or looking to upgrade, these answers provide clarity on proper use, maintenance, and selection.

1. What are hydraulic pullers used for?

Hydraulic pullers are made for industrial component removal, such as extracting bearings, gears, pulleys & also bushings from shafts. Their hydraulic mechanism allows for controlled force application, decreasing the risk of damage.

2. How do I choose the right hydraulic puller?

Find a puller based on the part size, force needed (pulling capacity) & jaw configuration (2-jaw or 3-jaw). Leading firmslike Orione Hydropower offer personalized pulling systems tailored to various applications.

3. Are hydraulic pullers safe to use?

Yes, when used correctly. Modern pullers from The Timken Company and Orione Hydropower are built with security features such as overload protection valves as self-centering jaws. Always follow providers guidelines for safe work.

4. Difference b/w mechanical & hydraulic pullers in general

Mechanical pullers are based on manual force phenomenon They can only do small or light tasks. On the contrary Hydraulic pullers use fluid pressure for high-force tasks. It provides more power with very less effort & is the best for heavy-duty tasks.

5. How do I upkeep my hydraulic puller?

Daily check hoses, seals, bolts as well as joints for damage or leaks. It's crucial for the long-term. Keep all parts clean & oiled & store the device in a dry & dust-free place. Proper upkeep of hydraulic extraction devices guarantees longevity & peak performance.

6. Can hydraulic pullers be used in tight spaces?

Yes, many models are designed for compact areas. Low-profile or single-acting cylinder pullers are perfect for confined workspaces.

7. Where can I buy quality hydraulic pullers?

Reputable brands like Orione Hydropower and The Timken Company offer high-quality products. You can find a wide selection through industrial suppliers and platforms like Amazon.

This pulling tools questions guide is intended to help users make informed decisions and get the most from their hydraulic puller systems.