- Hydraulic Tank Jack

- Pancake Jacks Plain Ram

- Pancake Jacks Threaded Ram

- Flat Jacks Single Acting

- Low Height Jacks Single Acting

- General Purpose Jacks Single Acting

- General Purpose Jacks Threaded Ram

- General Purpose Jacks Double Acting

- General Purpose Threaded Ram Double acting

- Alluminium General Purpose Threaded Ram

- Alluminium General Purpose Plain Ram

- Hollow Ram Jacks Single Acting

- Hollow Ram Jacks Double Acting

- Hydraulic Hand Pumps Aluminium

Pancake Jacks – Plain Ram: Compact Power for Heavy Lifting in Saudi Arabia

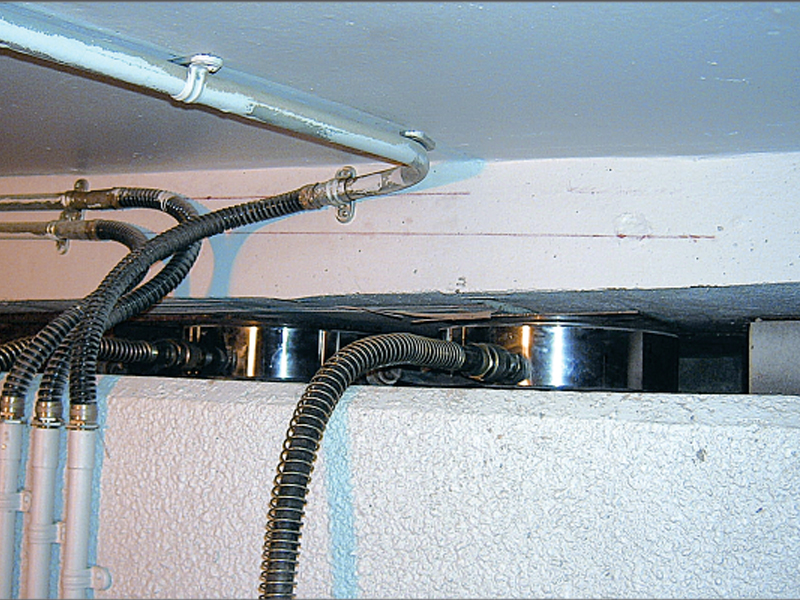

In the demanding environments of industrial maintenance, construction, and oilfield operations across Saudi Arabia, space-saving yet powerful lifting devices are essential. Pancake Jacks – Plain Ram variants provide a robust solution. Designed to deliver maximum force within a compact profile, these low-height hydraulic jacks are vital for operations where clearance is tight but performance is critical.

Unlike standard lifting systems, Pancake Jacks – Plain Ram models feature a sleek, flat design that fits under low-clearance equipment while delivering reliable vertical lifting force. This makes them ideal for use in energy sectors, shipyards, and construction sites where space limitations prevent the use of traditional jacks. These jacks are not only powerful and efficient but also easy to transport and position in challenging environments.

The rising demand for low-profile hydraulic jacks in Saudi Arabia highlights their importance in ensuring safety, speed, and accuracy in lifting operations. With high load-bearing capacity and minimal footprint, these Plain Ram Hydraulic Jacks are becoming the preferred choice for professionals seeking trusted performance and seamless integration into existing workflows.

Pancake Jacks – Plain Ram Overview

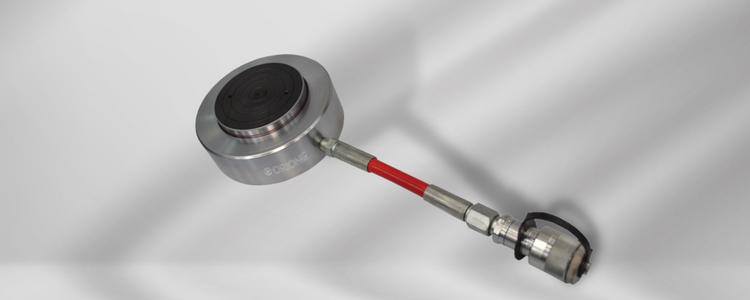

Pancake Jacks – Plain Ram are specialized low-height hydraulic cylinders engineered for lifting tasks in confined vertical spaces. Often referred to as Hydraulic Flat Jacks in the Saudi Arabian market, these jacks are built for high-force applications within a minimal height. They offer unparalleled strength, efficiency, and reliability—perfect for industries that require robust lifting solutions in tight spots.

Typically, these are single-acting hydraulic jacks. They use hydraulic pressure for extension and rely on gravity or the load itself for retraction. Many models are load-return types, which automatically retract after use—streamlining operations and reducing the need for complex control systems.

Built from hardened, high-grade steel, Pancake Jacks – Plain Ram are resistant to pressure and deformation. Their flat, compact design allows them to slide under machinery, structural components, and heavy loads requiring precise lifting. Each unit includes a wide base for enhanced stability and is designed to handle extreme loads while ensuring safety and structural integrity.

In Saudi Arabia’s construction, petrochemical, and industrial maintenance sectors, the demand for compact hydraulic cylinders continues to grow. These jacks are indispensable for tasks like machinery alignment, bridge section lifting, and critical component support during maintenance.

With professional-grade durability and a space-saving build, Pancake Jacks – Plain Ram are the top choice for experts needing performance, safety, and flexibility in tight working conditions across Saudi Arabia.

Capacity 10 - 200 ton / Stroke 10 mm / Max. Working Pressure 700 bar

| Capacity (ton) |

Capacity (kN) |

Stroke (mm) |

Model | Effective area (cm2) |

Oil cap. (cc) |

Closed height (mm) |

Wt. (Approx.) (kg) |

Suitable pump |

|---|---|---|---|---|---|---|---|---|

| 10 | 111 | 10 | OLPVL 10-10 | 15.9 | 16 | 30 | 1.2 | OHP-1P4-2-1.5 |

| 20 | 218 | 10 | OLPVL 20-10 | 31.2 | 32 | 35 | 2.2 | OHP-1P4-2-1.5 |

| 30 | 309 | 10 | OLPVL 30-10 | 44.2 | 44 | 40 | 3 | OHP-1P4-2-1.5 |

| 50 | 550 | 10 | OLPVL 50-10 | 78.5 | 79 | 50 | 6 | OHP-1P4-2-1.5 |

| 100 | 1077 | 10 | OLPVL 100-10 | 153.9 | 154 | 70 | 14 | OHP-1P4-2-1.5 |

| 150 | 1589 | 10 | OLPVL 150-10 | 227 | 227 | 75 | 22 | OHP-3P4-2-3 |

| 200 | 2199 | 10 | OLPVL 200-10 | 314.2 | 315 | 80 | 32 | OHP-3P4-2-3 |

Technical Specifications of Pancake Jacks

Comprehending the technical specifications of Pancake Jacks is essential for selecting the right tool for your lifting demands. Built to deliver reliable power in a space-saving form, these jacks are precisely engineered for industries across Saudi Arabia that demand strength, stability, and compact design.

The Pancake Jack blueprint begins with their low-profile height, often ranging from 25 mm to 60 mm in collapsed form. This makes them ideal for operations with very little vertical clearance. Despite their compact design, these jacks can handle impressive hydraulic load capacities, typically from 5 tons up to 150 tons, depending on the model. Each unit is pressure-tested for reliability and built to operate under maximum working pressures of 700 bar (10,000 psi).

These are single-acting, load-return jacks, meaning hydraulic power extends the piston while gravity or the load returns it. This design reduces complexity and enhances dependability during operations. The piston stroke lengths generally vary between 6 mm to 50 mm, offering precise lifting height control for low-clearance applications.

The jacks are constructed using hardened alloy steel or high-tensile carbon steel for excellent resistance against wear and hydraulic pressure deformation. Surfaces are typically nickel-plated or hard-chrome coated for corrosion resistance in Saudi Arabia’s harsh environment. The base diameters and piston head sizes are engineered to distribute load evenly, ensuring stability during use.

Optional accessories such as tilt saddles, handles, and couplers enhance portability and adaptability. Sealing technology includes high-pressure seals and anti-extrusion rings, preventing leaks and ensuring consistent performance.

Features and Benefits of Pancake Jacks

Pancake Jacks – Plain Ram are uniquely designed to address the specific lifting challenges found in confined workspaces. Their low-profile structure, coupled with high-capacity lifting power, makes them a standout choice for industries in Saudi Arabia seeking compact & efficient lifting answers. The combination of innovative design & strong materials guarantee that these jacks offer not only superior performance but also long-term reliability.

One of the key Plain Ram Jack features is its ultra-low collapsed height, which makes the jack to be easily inserted beneath machinery, beams & structures with minimal ground clearance. This makes it ideal for applications such as heavy devices upkeep, bridge lifting & alignment in non-going areas. Despite the low profile, these jacks are capable of offering lifting capacities up to 150 tons. It makes them a highly efficient lifting device option for demanding jobs.

One more major benefit lies in the single-acting, load-return design as it easify operation while guaranteeing dependable achievement. Once the hydraulic pressure is released, the load or gravity returns the piston to its original position. It discards the need for complex retracting mechanisms. This results in reduced upkeep & easier handling.

Constructed from durable hydraulic jack components such as hardened steel and corrosion-resistant coatings, these jacks are built to withstand harsh industrial environments. Their wide base & sleek dimensions guarantee stability & also ease of placing them also on uneven surfaces. Vaccuum seals & accuracy-manufactured pistons also aid to smooth process & then also prevent leaks.

Pancake Jacks also include their flexibility & compatibility with various hydraulic systems. It allows integration or changes into existing setups. With optional accessories like tilt saddles, handles, and hose couplers, these jacks offer flexibility to meet diverse lifting requirements.

In summary, Pancake Jacks – Plain Ram deliver a unique blend of compactness, strength, and ease of use. Their intelligent design and rugged construction make them a preferred choice for professionals across Saudi Arabia looking for performance-driven, space-efficient hydraulic lifting solutions.

Applications of Pancake Jacks

The use of Plain Ram Jacks in Saudi industries is becoming increasingly widespread, especially in sectors where precision, compactness, and heavy-duty lifting are essential. These hydraulic jacks serve as a major component in landscape with spatial limitations but high lifting demands. It fits perfectly into Saudi Arabia’s industrial & infrastructural expansion.

One of the most prominent areas of application is the oil and gas sector, where equipment handling, pipeline adjustments, and structural maintenance often occur in confined or restricted spaces. In such cases, oil and gas industry lifting equipment must be both powerful and compact—making Pancake Jacks the ideal solution. Their low-profile design enables technicians to position the jacks beneath heavy machinery or installations without the need for extensive disassembly.

The building industry in KSA also benefits superbly from the use of building hydraulic jacks like Pancake Jacks. From bridge work & beam alignment to cornerstone upliftment & tool upkeep. These items provide trusty & much needed stable support in scenarios where huge hydraulic systems cannot be used. Their maneuverability & effective load-bearing capabilities make them non-negotiable on dynamic job sites across the kingdom.

In manufacturing plants & industrial upkeep processes, hydraulic jacks usage in Saudi Arabia extend to machinery leveling, structural aid & alignment during putting of equipments. These functions often ask for quick setups & minimal disruption & compact tool which are all strengths of Pancake Jacks.

Furthermore, Saudi Arabia’s push for mega infrastructure projects and increased automation in maintenance and repair activities has fueled the demand for such specialized tools. Pancake Jacks with their robust built & adaptability, support this modernization by delivering safe & efficient lifting answers across a wide range of industries. It reinforce their position as a paramount tool in the country’s evolving industrial ecosystem.

Why Choose Orion Hydropower

When it comes to dependable lifting technology in the Kingdom, Orion Hydropower stands out as a trusted hydraulic jack supplier in Saudi Arabia, delivering products that meet the toughest industrial standards. With decades of knowledge in designing & manufacturing advanced hydraulic systems, we are dedicated to offering answers that align with the region’s evolving industrial needs.

As a reliable Pancake Jacks manufacturer, our engineering process focuses on precision, durability, and safety. Each jack is crafted using amazing-grade materials & out-of-this-world manufacturing techniques, ensuring superior performance and longevity, even in the most demanding environments. Our high-quality hydraulic equipment is rigorously tested to international standards before it reaches our customers, guaranteeing consistent reliability under high pressure and extreme conditions.

Our dedication to Saudi Arabia hydraulic solutions goes beyond just supplying items. We work closely with users across the Kingdom—from oil & gas enterprises to infrastructure developers—to offer tailored hydraulic jacking systems that suit their exact needs. Whether it’s a custom stroke length, load capacity, or enhanced corrosion protection for desert conditions, our team ensures your solution is built to perform and last.

Orion Hydropower’s focus on regular innovation, responsive user support & adherence to global quality benchmarks positions us as a dependable partner in the hydraulic lifting sector. We don’t just provide equipment—we deliver confidence, performance, and long-term value.

In a market that demands both strength and precision, Orion Hydropower delivers with integrity and expertise. By choosing us, you’re finding a partner in us who understands the unique challenges of your operations & then delivers Saudi Arabia hydraulic solutions that meet them head-on.

Frequently Asked Questions (FAQs)

Q1: What are Pancake Jacks used for?

A: Pancake Jacks are fundamentally used in applications requiring heavy lifting within confined vertical spaces. Basic industries include oil and gas, construction, shipbuilding & also plant maintenance. Their low-profile build makes them the best choice for situations where space is limited but lifting power is essential.

Q2: How do these jacks differ from standard hydraulic jacks?

A: The key difference is in height & form factor. Pancake Jacks are very much shorter in height compared to standard jacks. It allows them to be inserted into tight areas. They are specifically made for low-clearance lifting tasks without any effect on load capacity.

Q3: What is the typical load range for Pancake Jacks?

A: Load capacities can vary depending on the model, but most of the Plain Ram Hydraulic Jacks are available in ranges from 5 tons up to 150 tons. It provides flexible options for light to amazingly heavy-duty operations.

Q4: How should I maintain my Pancake Jack for optimal performance?

A: Regular upkeep & check includes inspecting hydraulic seals for wear, checking oil levels, cleaning the surface to avoid dirt buildup & also ensuring there are no leaks. Proper upkeep or check of Pancake Jacks prolongs their lifespan & guarantees safe operation.

Q5: Are these jacks compatible with standard hydraulic pumps?

A: Yes, most Pancake Jacks models are made to work seamlessly & effortlessly with standard hydraulic pumps. However, always verify compatibility based on pressure & flow specifications.

Request A Quote